Table of Content

Revolutionizing Tiny Tube Cutting

What are the Key Features of the R1 Series Tube Laser Cutting Machine?

Applications of R1 Tube Laser Cutting Machine Across Industries

Why Choose Laser Technologies?

Benefits of the R1 Series Tube Laser Cutting Machine

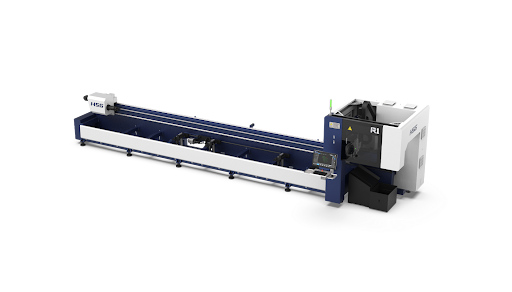

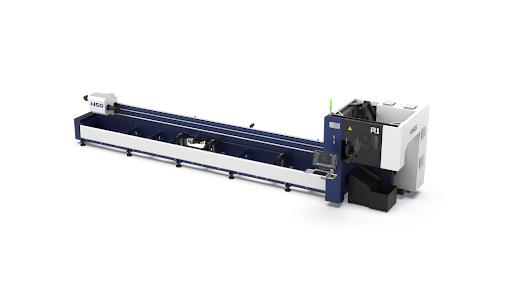

In the dynamic world of modern manufacturing speed, and adaptability are indispensable. Laser Technologies, a pioneer in advanced laser solutions, has continually set benchmarks for innovation. How does the R1 Series Innovate Tube Laser Cutting? The R1 Series Tube Laser Cutting Machine epitomizes this spirit of innovation, delivering advanced automation solutions for tiny tube cutting. Tiny Tube Laser Cutting Machine is designed for small and intricate applications. The R1 Series is transforming industries that demand meticulous precision and efficiency.

Revolutionizing Tiny Tube Cutting

The R1 Series is engineered for manufacturers with small-diameter tubes, such as those used in medical devices, electronic components, and fine industrial parts. This machine combines precision engineering with advanced automation to meet the unique challenges of tiny tube laser cutting. The R1 Series Laser Cutting features an automatic material rack capable of loading materials in just 20 seconds, accommodating tubes ranging from 20mm to 120mm and lengths 4m to 6.5m.

What are the Key Features of the R1 Series Tube Laser Cutting Machine?

The R1 Series features an automated Laser Cutting System, real-time monitoring, precision tube profile processing, and seamless integration with other manufacturing processes for increased efficiency and productivity. How does the R1 Series Innovate Tube Laser Cutting?

1. Chuck Jumping Technology for Minimal Tailings

The R1 Series machine has a unique chuck-jumping mechanism that significantly reduces tailing lengths, even with large amplitude cuts. Modifying the chuck displacement, along with its high-precision cutting capabilities, guarantees accuracy for long tube cuts. An optional servo chuck-jumping system can be installed to boost efficiency by providing quick and accurate chuck movement.

2. Follow up Loading and Unloading

The R1 system streamlines operations by seamlessly loading raw materials and unloading finished components, minimizing downtime. These Laser-cutting Machines feature an automatic material rack capable of loading materials in just 20 seconds, accommodating tubes ranging from 20 mm to 120 mm and lengths of 4 m to 6.5 m.

3. Intelligent Bus Operating System

The R1 Series is a versatile processing system with an intelligent bus operating system, nesting software, and professional price calculations for efficient production workflow management.

4. Exceptional Cutting Precision

At the heart of the R1 Series lies its advanced laser cutting technology, which ensures micro-level precision. The machine is capable of cutting tubes with diameters as small as 1mm, meeting the high-precision requirements of industries such as medical devices and electronics. Its ability to achieve intricate geometries without compromising accuracy makes it a leader in its class.

5. Compact Design for Versatile Applications

The R1 Series features a compact and ergonomic design, making it suitable for manufacturers with limited floor space. What materials can the R1 Series process with precision? Despite its small footprint, the machine delivers high-performance capabilities, handling a wide variety of materials, such as :

- Stainless steel

- Mild steel

- Aluminum

This versatility allows the R1 Series to cater to diverse applications, from precision instrumentation to lightweight components.

6. Advanced Automation Available

The R1 Series incorporates automation to enhance productivity and reduce manual intervention. With precise alignment and handling, the R1 ensures consistent cutting quality and eliminates the need for time-intensive manual adjustments.

7. Energy Efficiency

Laser Technologies has prioritized sustainability in the design of the R1 Series. The machine operates with high energy efficiency, reducing power consumption and operational costs without compromising performance.

Applications of R1 Tube Laser Cutting Machine Across Industries

The R1 Series is designed to meet the unique demands of industries where precision and miniaturization are critical:

1. Medical Devices

The medical sector requires high-precision components for instruments such as catheters, stents, and surgical tools. The R1 Series delivers the accuracy needed to produce these delicate parts, ensuring compliance with stringent industry standards.

2. Electronics

In the electronics industry, where compact and precise components are essential, the R1 Series excels in creating intricate patterns and shapes with burr-free edges. Its capabilities are ideal for manufacturing connectors, heat sinks, and other small components.

3. Precision Engineering

For industries focusing on custom designs and fine details, the R1 Series provides the versatility to handle unique requirements. From prototype development to full-scale production, it ensures flawless execution.

4. Aerospace

The aerospace sector benefits from the R1’s ability to cut lightweight materials with high precision, essential for crafting components used in avionics and instrumentation.

Why Choose Laser Technologies?

Laser Technologies has established itself as a trusted partner for manufacturers worldwide, and the R1 Series exemplifies the company’s commitment to Innovative Tube-cutting Technology and customer satisfaction. Here’s why Laser Technologies stands out:

1. Proven Expertise

With years of experience in laser technology, Laser Technologies delivers solutions that are tailored to the specific needs of diverse industries. The R1 Series is a testament to their ability to innovate and address market demands.

2. Unmatched After-Sales Support

At Laser Technologies, customer satisfaction extends beyond the sale. The company provides:

- Training: Operators receive thorough training to ensure seamless adoption and efficient operation of the R1 Series.

- 24/7 Technical Support: A dedicated team of experts is available to assist with troubleshooting and maintenance.

- Regular Maintenance Plans: Proactive service plans help maintain peak performance and extend the machine’s lifespan.

3. Customisation and Scalability

Laser Technologies understands that no two manufacturers are alike. The R1 Series is customizable to meet specific production requirements, ensuring a solution that aligns with your goals.

Benefits of the R1 Series Tube Laser Cutting Machine

How Does the R1 Series Innovate Tube Laser Cutting with Advanced Automation? Investing in the R1 Series Laser Cutting Machines offers a host of benefits for manufacturers, including:

1. Precision and Consistency

The machine’s advanced laser technology guarantees consistent quality, even for intricate designs and challenging materials.

2. Enhanced Productivity

Automation features reduce downtime and manual labour, enabling faster production cycles and higher throughput.

3. Cost Efficiency

The energy-efficient design and optimized material usage result in significant cost savings over time.

4. Compact and Versatile Design

The R1’s small footprint and versatility make it an ideal solution for manufacturers with limited space and diverse application needs.

Conclusion

The R1 Series Tube Laser Cutting Machine by Laser Technologies is more than just a cutting tool; it’s a leap forward in precision, efficiency, and automation. With its advanced features and unmatched versatility, the R1 Series is transforming industries that demand excellence in tiny tube cutting.

By choosing Laser Technologies, manufacturers not only gain access to an exceptional product but also benefit from a partnership that prioritizes innovation, reliability, and customer success. Experience the future of tube laser cutting with the R1 Series and unlock new possibilities for your business.