Table of Content

- Understanding the Universal Tube Laser Cutting Machine

- Key Features of the Universal Tube Laser Cutting Machine

- Applications Across Industries

- Why Choose Laser Technologies?

- Conclusion

In the world of modern manufacturing, timeliness, effectiveness, and exactness are critical to staying ahead in a competitive market. Laser Technologies, a pioneering force in laser-cutting technology, offers a solution that provides tube laser-cutting machines. This machine is designed for a wide range of industries such as automotive, aerospace, and construction. It combines high-precision capabilities with user-friendly features and unmatched versatility, making it an ideal choice for industries needing flawless tube and pipe cutting.

The most common features and benefits of tube laser cutting machines include high precision cutting, versatility in cutting various materials, increased production efficiency, and reduced material waste.

Understanding the Universal Tube Laser Cutting Machine

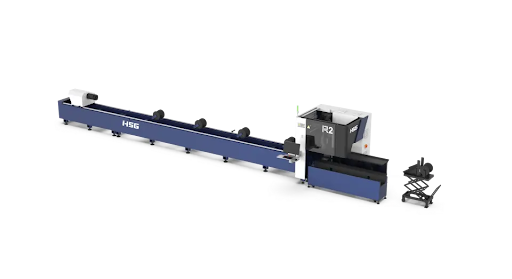

Laser Technologies Universal Tube Laser Cutting Machine R2 is a testament to the company's dedication to providing high-quality, reliable, and efficient laser cutting solutions. It is specifically engineered to handle the cutting of a variety of tubes and profiles, including round, square, rectangular, and special-shaped tubes. By combining nesting software with user-centric design, the R2 model ensures smooth, precise cuts with minimal material waste, even for the most complex shapes and geometries.

Key to its appeal is the R2’s innovative design that integrates advanced features and high-performance components. Laser cutting technology for tubes controls a highly efficient laser source and a robust frame, offering manufacturers a cost-effective, versatile, and reliable solution for tube cutting.

Key Features of the Universal Tube Laser Cutting Machine

Tube Laser Cutting Machine Suppliers in India offer high-precision cutting capabilities for a variety of materials, making them ideal for industries. The Universal Tube Laser Cutting Machine R2 stands out for its versatility, efficiency, and user-friendly interface.

1. Advanced Laser Source for Exceptional Precision

The Universal Tube Laser Cutting Machine R2 is equipped with a powerful laser source that provides exceptional beam quality and cutting precision. Laser Cutting for Metal Tubes allows for superior performance, delivering accurate and clean cuts with high-edge quality, whether you are working with thin-walled or thick tubes. Laser Technologies lasers are designed to minimise energy consumption while providing rapid cutting speeds, enhancing both productivity and cost-efficiency.

2. High-Speed Cutting and Efficient Performance

Laser cutting is known for its speed, and the Universal Tube Laser Cutting Machine R2 takes this to the next level. The high-speed cutting capabilities are made possible by its advanced drive systems and optimised laser beam focus, ensuring that cuts are made with minimal heat distortion and burr formation.

The machine also features fast material loading and unloading systems, ensuring that the production process is continuous. This design dramatically reduces the downtime between operations, which translates into enhanced throughput and improved overall productivity.

3. Automatic Tube Loading and Unloading

The Universal Tube Laser Cutting Machine R2 is designed to reduce manual labour by incorporating automated tube loading and unloading systems. These automatic loading processes streamline the workflow, improving the overall efficiency of production lines and reducing the potential for errors caused by manual handling.

This feature also makes the R2 ideal for high-volume production, as it allows for continuous operation without requiring constant operator involvement. The automated loading system is equipped with intelligent sensors that align and position tubes accurately, further enhancing the system’s precision.

4. User-Friendly Interface

Laser Technologies recognised the importance of ease of use in high-tech machinery, and the Tube Laser Cutting Machine R2 is equipped with a highly intuitive interface. The machine’s user-friendly control system simplifies the overall operation, reducing the learning curve for new operators.

With customisable settings and pre-programmed cutting parameters, the R2 is designed to handle both standard and complex cutting tasks with ease.

Also Read Complete Guide On Laser Cutting Machine

Applications Across Industries

Tube laser cutting technology offers efficiency, making it ideal for a wide range of industries such as automotive, aerospace, and construction. These advanced tube cutting machines ensure high-quality results.

1. Automotive Industry

In the automotive sector, manufacturers rely on tube cutting to produce parts for vehicle frames, exhaust systems, and other critical components. The Universal Tube Laser Cutting Machine R2 excels in providing precise, clean cuts for these components, ensuring they meet stringent quality standards and performance specifications.

2. Aerospace

Aerospace manufacturers require tubes and profiles with exact dimensions and minimal tolerances. The R2’s precision cutting capabilities make it an invaluable tool in aerospace applications, where even the smallest variations can impact the overall functionality and safety of the end product.

3. Construction and Architecture

In construction, tubes and profiles are used for structural frameworks, scaffolding, and architectural elements. The Universal Tube Laser Cutting Machine R2 ensures that these components are cut with the utmost accuracy and minimal material wastage, improving the overall efficiency of construction projects.

4. Furniture Manufacturing

The demand for custom-designed metal furniture continues to grow, and the Universal Tube Laser Cutting Machine R2 is perfectly suited to meet these needs. With its ability to cut tubes into intricate shapes and profiles, the R2 enables the production of high-quality, customised furniture components for both residential and commercial markets.

Why Choose Laser Technologies?

Laser Technologies has long been a trusted leader in laser cutting machines, and it is known for its technology, precision, and customer-centric approach. Manufacturers gain access to a wide range of high-performance solutions by choosing Laser Technologies, including the Universal Tube Laser Cutting Machine R2, backed by the company’s expertise in laser cutting technology.

Laser Technologies distinguishes itself in the industry through its constant commitment to quality, innovation, and customer satisfaction. By offering solutions and advanced laser technologies, it empowers industries to achieve operational excellence. A key differentiator for Laser Technologies is its complete post-sale service, which offers exceptional support to help customers maintain peak machine performance over time. This commitment to continuous service development nurtures long-term partnerships, establishing the company as more than just a vendor but as a trusted partner dedicated to the success and growth of its clients.

Discover how the Universal Tube Laser Cutting Machine R2 can transform your manufacturing process.

Book a Demo Today and see the power of precision, efficiency, and innovation in action!

Conclusion

Features of Tube Laser Cutting Machine R2 from Laser Technologies include precision cutting capabilities, efficient production processes, and reliable performance. Choosing Laser Technologies means investing in a machine that not only meets the demands of modern manufacturing but also comes with exceptional after-sales support, ensuring continuous, high-performance operation for years to come.

The features and benefits of tube laser cutting machines by Laser Technologies make it a top choice for companies looking to enhance their production capabilities and stay competitive in today's market.