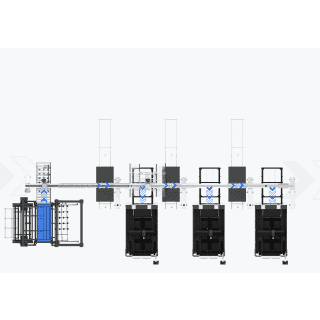

ARW & PT65

Automatic Pallet Racks for Sheet and Tube Metals

This Product is unavailable.

Download Brochure

This Product is unavailable.

Download Brochure

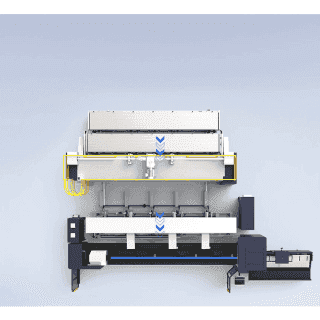

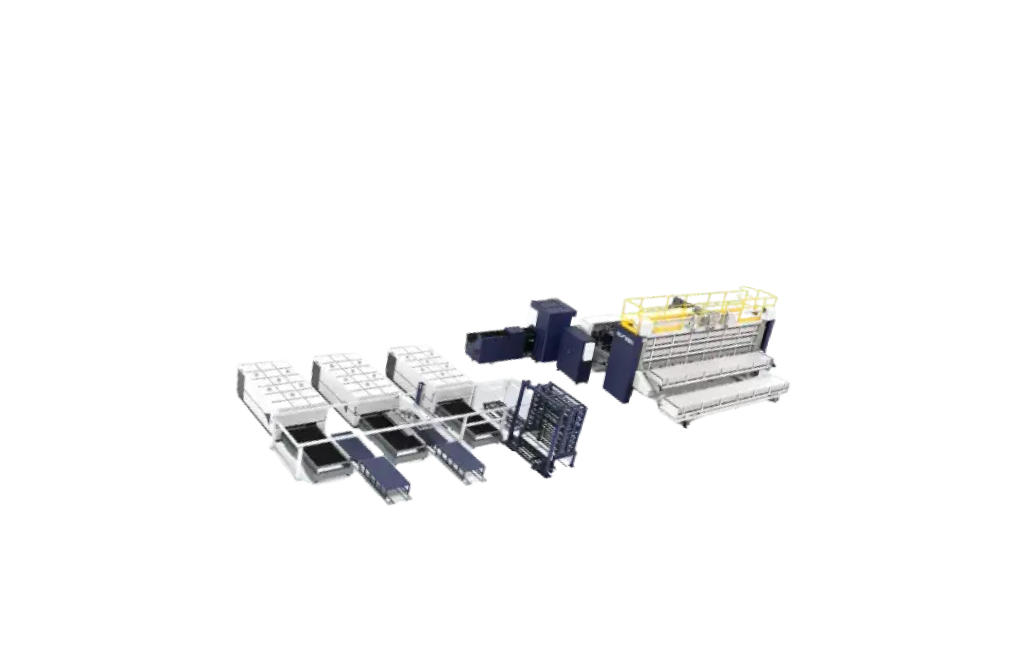

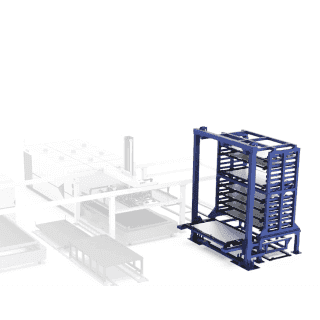

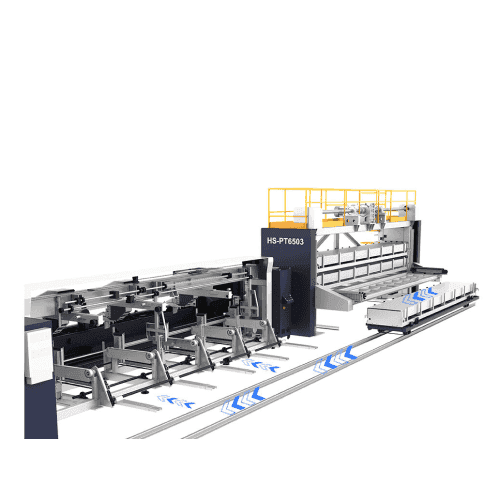

Sheet metals are stored in a batch and systematic way for the convenience of easy invocation and quick production. This tower-type stereoscopic pallet rack will maximize cubicle space and accommodate more sheet metals compactly. The disordered storage manner will become a thing of the past, a prelude to efficient production.

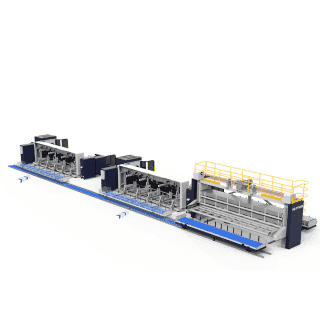

The production starts by itself according to relevant plans. Its precision control system has a function of intelligent management that will invoke sheet metals for loading and permit unmanned cutting. Except for saving labour costs, misoperation caused by manual work will also be effectively avoided.

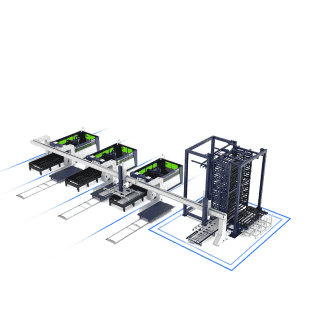

A set of automatic loading & unloading systems can simultaneously serve for several cutting machines to make efficient production possible. Except for a reduction in energy consumption, the utilization of workshops will also be enhanced.

24-hour non-stop production is made possible by full-automatic and unmanned work even at night. Its intelligent arrangement of tasks allows self-acting planning according to production plans. With an intelligent reloading function, all types of tubes will be changed at will.

Raw materials and well-prepared sheets can be automatically changed in syn with processing. Thus, reloading duration is minimized to improve the whole production efficiency.

A pallet rack can serve for several tube laser cutting machines, expanding production capacity and saving space costs. Many kinds of tubes will be accurately loaded to the appointed tube laser cutting machines. Its flexible processing is a good carrier of digital-based production concepts conveyed by Industry 4.0.