Photon X - iMark Laser Marking Machine

The best fiber laser machine

The beam quality of the laser machine is extremely high, allowing marking at a higher frequency than allowed by traditional technology and with smaller details thanks to the good control of all parameters.

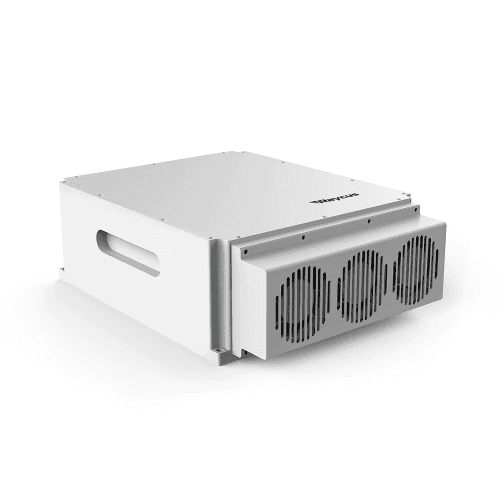

Due to a good match between the laser pump and cavity design, the electric power supply demanded by the system is 5-10% less than that required by traditional laser systems. Furthermore, cooling is yielded by a small built-in system so that the noise and size of the machine are reduced.

The output parameters can be selected by the operator; he/she can choose the average power from zero to the highest value, and pulse repetition frequency. The laser beam spot size, thanks to the dynamic modification of the working distance and marking field, can vary accordingly. This enables them to change the laser beam quality and to yield markings with different spot sizes.

The laser machine comes with a standard with Max. Raycus, JPT, or IPG fiber laser source according to the customer's requirements. It is a perfect laser beam with a long life. Here are some of its major highlights

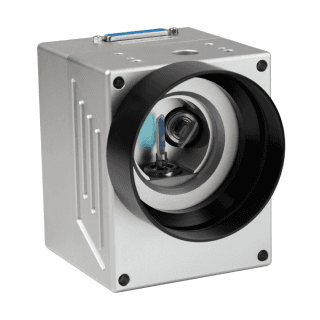

Featuring an air-spaced design and anti-reflective coating, our compact Fθ field lens ensures excellent throughput and durability with less than 1% distortion.

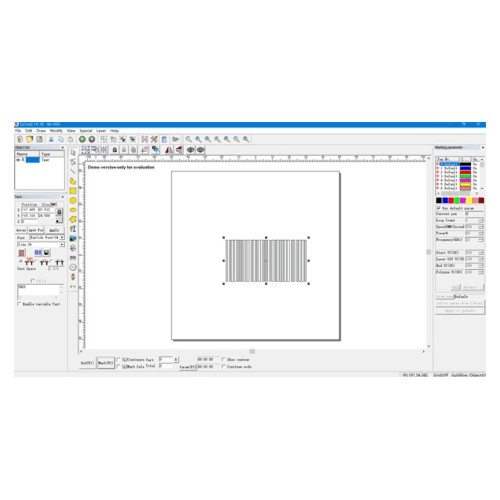

Our laser marking machine comes with a Beijing JCZ board card and EzCad2 software compatible with Windows 7, 8, and 10. It is professional engraving offering stable performance with high reliability. Additionally, it’s intuitive and easy to use and can also use images from AutoCAD, CorelDraw, Adobe Illustrator, Photoshop, etc.

The laser machine’s high-speed Galvo-Tech digital galvanometric system reduces delays and improves your engraving speed. Check out its highlights

| Model | iMark-20 | iMark-30 | iMark-50 |

|---|---|---|---|

| Output Power | 20 W | 30 W | 60 W |

| Wavelength | 1064 nm | ||

| Power Adjustment | 0 to 100 % | ||

| Cooling | Air Cooled | ||

| Min. Line Width | Min. 0.03 mm (Depend on Material) | ||

| Max. Speed | Max. 10000 mm/s (Max. Linear Speed) | ||

| Marking Depth | 0.01~0.3mm (Depends on Material) | ||

| Min Character Height | 0.5 mm | ||

| Marking Range(mm/s) | 110 mm X 110 mm (Standard) Optional: 200 x 200 mm, 300 X 300 mm | ||

| Supporting Format | Support PLT, DXF, BMP File etc., Using SHX TTF Character Storage Directly | ||

| Single Pulse Energy (mj) | 1.0@20KHz | 1.0@30KHz | 1.0@50KHz |

| Repetition Frequency Range | 20-60 KHz | 30-60 KHz | 50-100 KHz |

| Output Power Stability | <3% | ||

| Beam Quality(M2) | <1.5 | <1.8 | |

| Pulse Width(ns) | 90-130 KHz | 90-150 KHz | |

| Max Power Consumptions | 400 Watt | 450 Watt | 650 Watt |

| Specifications are liable to change without prior notice. | |||