High-End Double-Head Vertical CNC V Grooving Machine

Stable, accurate and quiet laser machine

The operating platform features a large touchscreen display that follows the operator's movements for quick and efficient operation.

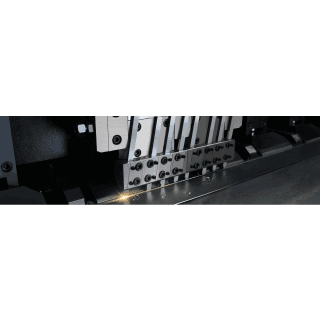

Supports various automatic grooving programs like one-way, reciprocating, and fixed-point grooving. The tool holder is driven by a servo motor, providing blade feeding accuracy of ±0.01mm.

The control system is independently researched and developed by GHBM and has obtained a national patent. It addresses the two major issues of simplifying the programming process and enhancing production efficiency.

Offers simple operation with a low learning curve, supporting multi-slot grooving programming and the programming call function.

Full servo motor drive, the whole machine processing accuracy are ≤ 0.03mm. And the processing length range is 200 mm-4200 mm.

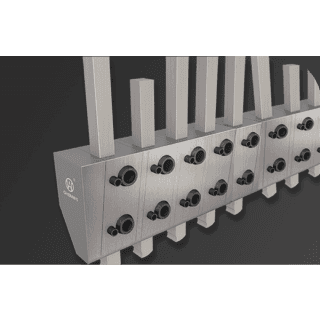

The cutter block is made of high-quality steel after quenching treatment to obtain high strength and high wear resistance.

It can slide left and right along the linear guide and can be folded to save space.

LED lighting equipment can illuminate the work area with low energy consumption and high brightness.

The plate is fed into the machine by a back clamp on the back support device. And the feeding tolerance is≤±0.03mm. The plane of the pallet is strengthened to make it more wear-resistant

| 4Machine Frame Material | Q235 | Dimension·Length | 5360 mm |

|---|---|---|---|

| Blade Holder Material | alloy steel | Dimension·Width | 2800 mm |

| Max. Processing Length | 4200 mm | Dimension·Height | 2325 mm |

| Max. Processing Width | 1600 mm | Grooving Speed(X-axis) | 4-28 m/min |

| Processing Thickness | 0.3 mm-6 mm | Blade Return Speed(X-axis) | 0-80 m/min |

| Min. V-trough Edge | 8 mm | Back Gauge Speed | 0-6 m/min |

| Diving System | 3 axis cnc control(x/y/z) | Blade Holder Speed(Vertical) | 0-0.5 m/min |

| Servo Motor Power | 4.2 KW | Back Gauge Resolution(Y-axis) | ±0.01 mm |

| Display | 15 inch HD LCD touch screen | Back Gauge Stoke(Y-axis) | 1400 mm |

| Storage | 32 K / 14000 steps | Blade Holder Resolution(Z-axis) | ±0.01 mm |

| Driving Mode | ball screw / inear guide / gear rack | Blade Holder Stroke(Z-axis) | 10 mm |

| Machine Weight | 13500 Kg | Hydraulic System | 1.5 KW / 35 L / 10 Mpa |