All GCC products are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (PB-free). GCC will continue to provide environmentally friendly products to protect the earth for future generations.

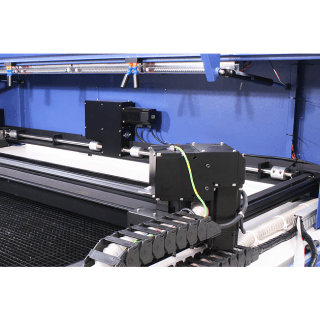

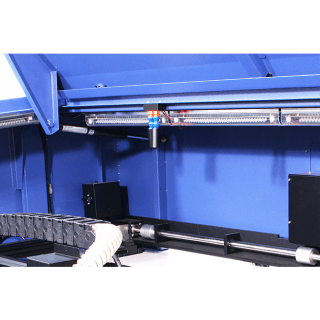

High torque and high-speed AC servo motor assure long motor lifetime and high precision. A lightweight and high-strength structure together with an AC servo motor and steel cord belt to provide first-class stability and accuracy.

T-500 embrace an extraordinary control system and rigid motion system allowing users to create top-notch vector scribing quality with high speed.

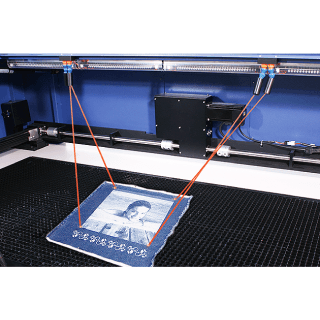

Developed by LaserPro, AAS is an exceptionally user-friendly operation which offers accurate and faultless contour cutting by automatically tracking the position of graphics.

Material positioning is made extremely easy by the use of 4 red beam diodes. Simply aim each red beam diode at distinct points on the material and the red beam becomes a very useful positioning tool to replicate previous jobs precisely.

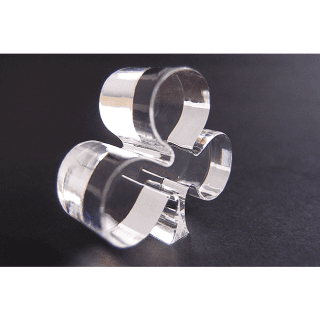

T500 delivers high-cutting quality with LaserPro's unique laser firing control technology. Up to 200W output power options, GCC LaserPro T500 can cut through 1" (25 mm) acrylic in a single pass with a smooth finish and unmatched clear cutting edge.

T500 persists with GCC LaserPro's excellent engraving capability. Having cutting and engraving capability in one product, no more time wasted on switching materials from the cutting and engraving machine. Compared to conventional cutting products, it is difficult to have a good and consistent raster performance with a large working area, but the T500 can.

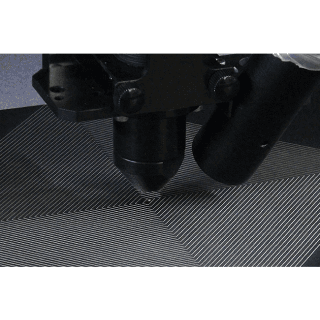

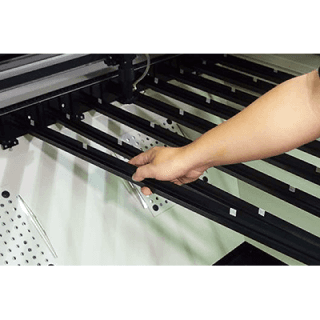

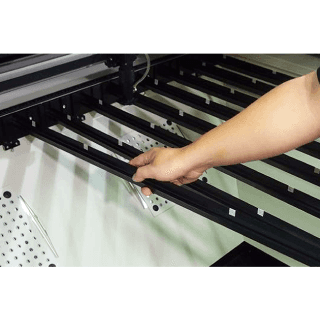

Unique cutting table with tipped bars that can be easily adjusted without tools to create different levels of working depths. The cutting table of T500 reduces laser reflections and delivers a clear cutting edge.

An LED light module that illuminates the working space and makes every engraving detail easy to see.

The grid-cutting table is an ideal pal for laser cutting. It lifts the work piece off the work table from hitting by laser reflection while supporting it with a reinforced grid design. The dust and vapour created during laser cutting are then taken away effectively through the grid by down vacuum exhaust (suggested using SmartBOX™ together). Rather than handling rigid materials, the grid cutting table also helps to fix flexible materials with the aid of down vacuum SmartBOX™ to keep constant focus distance and consistent cutting results. A clean and better cutting quality is achieved from this technique.

A design with doors on both ends to accommodate extremely long working pieces, front door without the need for a screwdriver.

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using a network connection. Free your designers with great flexibility and maximum machine versatility.

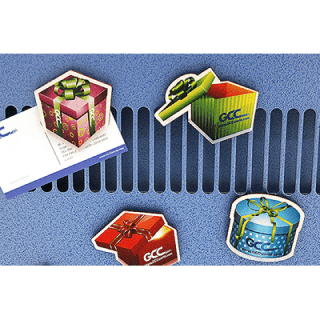

Bridge Cutting function diversifies the laser cutting into packaging prototyping and fulfils versatile requirements. Define the cutting gap to create the dashed line effect from a user-friendly print driver interface.

| Specification | Details |

|---|---|

| Working Area | 1300 x 905 mm (51 x 35 in.) |

| Z-axis | 127 mm (5 in.) |

| Wattage | 60W~200W |

| Max. Working Speed | 40 IPS |