PhotonX - iCut

A complete solution for laser processing large format materials

This Product is unavailable.

Download Brochure

This Product is unavailable.

Download Brochure

The Aluminium base of the guide rail is relatively resistant to corrosion and is inlaid with a steel shaft. Compact structure and beautiful appearance. Equipped with a U-shaped bearing roller. Fast running speed and low noise. Firm, steady, and high precision without vibration while cutting at high speed. The positioning accuracy is very high, and less wear and tear can maintain high cutting accuracy.

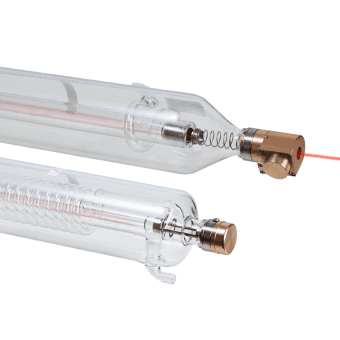

To make high-power and top-quality laser beams, Laser Technologies offers CO2 laser tubes having high optical quality, strong cutting force, and high stability. Advanced vacuum coating technology has further improved the power and service life of the laser tubes. Our CO2 Laser Tubes produce stable laser beams for precise engraving on a wide variety of materials. Glass CO2 Laser Tube with an estimated lifetime of up to 6,500 operation hours depending on power setting usage and water-cooling performance

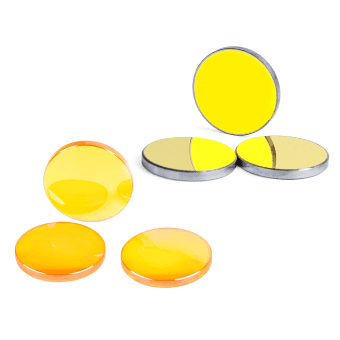

The imported USA ZNSE double-side antireflection film is mainly used to decrease or eliminate the reflective lights from the optical lens, prisms, plane mirrors, etc. so to increase light penetration and decline or eliminate stray lights. There are two kinds of commonplace laser mirrors, namely molybdenum laser mirror and silicon laser mirror, and Laser Technologies offers both top-notch laser mirrors with high reflectivity and high durability

The new Photon X series was build on high-speed multi communication system. you can connect to your machine by USB cable, LAN network cable and transfer your data by USB Flash disk. The machines has 256MB memory, easy use color screen control panel. with off-line working mode when your electricity is down & open machine will run on stop position.

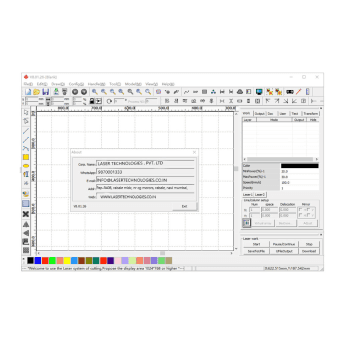

Ruida laser controller CNC system is a new generation of laser engraving and cutting control system. In addition to high hardware stability, high voltage, or electrostatic suppression, and a friendly TFT human-machine display. The system has more powerful software features, including a perfect four-axis motion control function, large-capacity file storage, two adjustable digital laser power control interfaces, stronger compatibility USB driver, multiple universal/dedicated IO control, as well as this system can communicate with PC via USB2.0 or Ethernet. RDWorks software is inexpensive, feature-rich, and under active development with great support. Creates quick and simple G-codes, a set of instructions for the laser, to communicate the amount of power to use and what to engrave. Supports AI, DXF, PLT, DSB, DST vector formats and BMP, JPG, GIFT, PNG bitmap formats

| Model | iCut 9060 | iCut 1390 | iCut 1410 | iCut 1610 | iCut 1810 | iCut 1325 |

|---|---|---|---|---|---|---|

| X,Y Cutting Area | 900X600mm | 1300X900mm | 1400X1000mm | 1600X1000mm | 1800X1000mm | 1300X2500mm |

| Laser Power | 80W /90W / 100W | 100W / 130W | 100W / 130W | 100W / 130W | 100W / 130W | 100W / 130W / 150W |

| Laser Source | Sealed Glass Co2 Laser Tube | |||||

| Travelling Speed | 400 mm/s | |||||

| Reposition Accuracy | 0.02 mm | |||||

| Minimum Letter Size | 1.0 mm (English Font) | |||||

| X Y Movement System | Belt Transmission | |||||

| Z – Axis Movement | Automatic Up to 180 mm (optional) | |||||

| Power Adjustment | 1 to 100 % | |||||

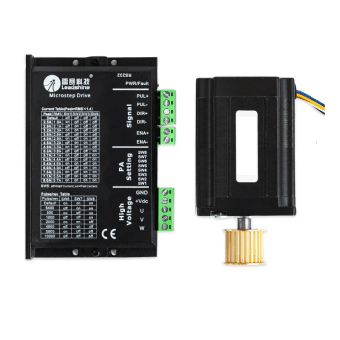

| Driving System | Stepper Motor | |||||

| Operating System | Win 7/8/10, 32/64 bit | |||||

| Memory Buffer | 128 MB | |||||

| Fume Extraction System | External exhaust system with minimum flow rate 1200m3/h (CFM 706 ft3/h). Connection output 4″ Diameter | |||||

| Power Consumption | 2 KW | 2 KW | 2 KW | 3.5 KW | 3.5 KW | 4.3 KW |

| Specifications are liable to change without prior notice. All trademarks mentioned are property of their respective owners. | ||||||