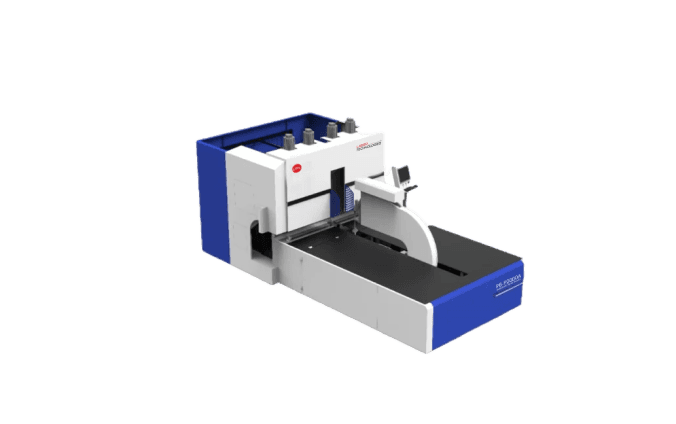

Automatic Panel Bender

Improves Production Efficiency & Reduce Labor Cost

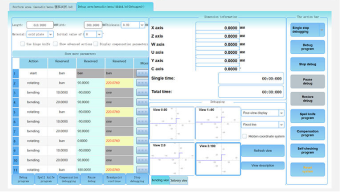

The machine has a professional Panel Bender control system, that realizes true 15-axis concurrent linkage. Also, its response is quick and smooth. The function and stability has been proven by more than 1000 users.

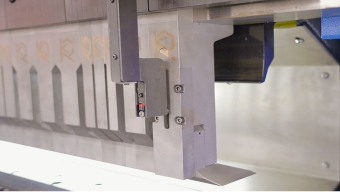

The machine has a Servo controlled hinge tool that helps avoid material deformation, precision loss, side shovel force and scratches

The laser machine has brand new designed upper-pressure tools with special material, enhanced hardness, accuracy consistency and stability. Additionally, it has upper-pressure tools with the function of quick release and installation, easier and faster to change the tools.

The upgraded version of the bus control system has strong and diverse functions, which makes users enjoy a green and intelligent control system through simple operations.

| Model | P1500A | P2000A | P2500A |

|---|---|---|---|

| Number of axis | 23 | 25 | 25 |

| Maximum bending speed | 0.2S/TIME | ||

| Maximum bending width | 1500MM | 2000MM | 2500MM |

| Maximum bending size( L*W ) | 1500MM*1300MM | 2000MM*1300MM | 2500MM*1300MM |

| Bending height | 170MM | ||

| The rated voltage | 380V | ||

| Machine weight | 10 Tons | 20 Tons | 25Tons |

| Minimum size of four-side bending | 180*370mm | 180*370mm | 200*370mm |

| Noise | ≈50db | ||

| Machine dimension | 4800mm*2100mm*2850mm | 5550mm*3050mm*3100mm | 5750mm*3200mm*3400mm |