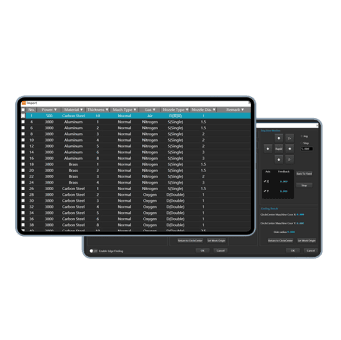

While cutting sheets of different metals and thicknesses, the machine handler can invoke cutting-edge technology from the database.

Comprises different thick sheet cutting technologies like air cutting, counterboring technology, perfect finish cut (PFC), lightning-fast piercing, etc.

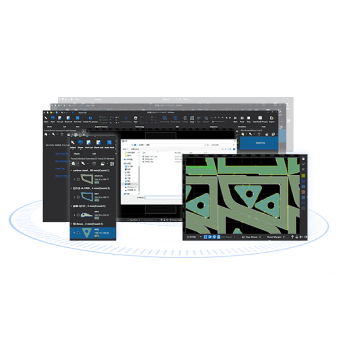

Less operational time is required as the machine optimizes the cutting path.

A smart typesetting algorithm is used for the increase of material utilization.

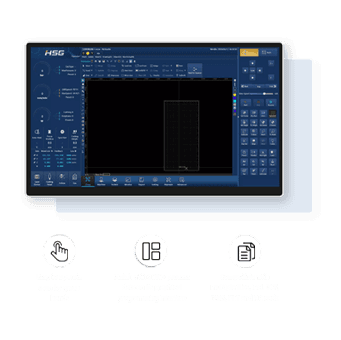

Enables data transmission via EtherCAT bus and features fast speed and stability. The function-rich system is easy to operate. Even green hands can cut high-quality samples.

It is an open-type structure with a single platform. It can load from the front, left, and right sides. Additionally, it takes only one day to get started.

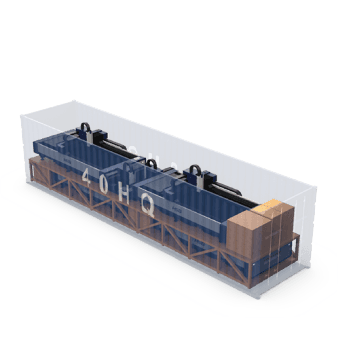

Ship four C3015 in one 40HQ standard container, as a result, save overseas freight and fit for customers who prefer bulk orders.

| Model | Power | Processing format (L*W) | X/Y-axis Positioning Accuracy |

|---|---|---|---|

| C3015 | 1500W-6000W | 3048mm*1524mm | ±0.05mm/m |

| C4020 | 1500W-6000W | 4064mm*2032mm | ±0.05mm/m |

| C6025 | 3000W-20000W | 6096mm*2540mm | ±0.05mm/m |

| C12025 | 12000W-60000W | 12500mm*2540mm | ±0.05mm/m |

| C13030 | 12000W-60000W | 13100mm*3100mm | ±0.05mm/m |

| Specifications are liable to change without prior notice. | |||