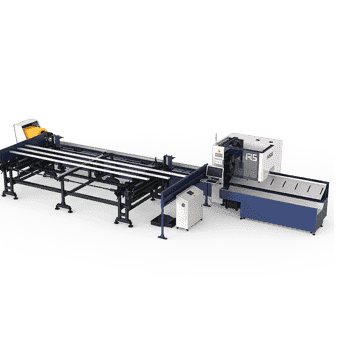

R5 II Series

Professional full-automatic tube laser cutting machine (1500- 4000W)

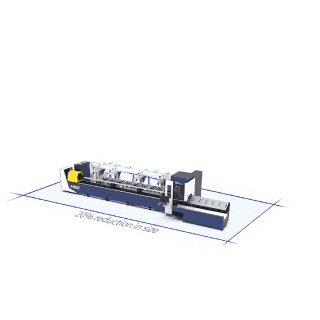

- Small in size

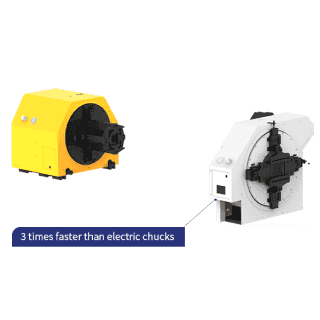

- Unique squircle pneumatic checks

- Min. Tailing 85mm

- Packed in standard containers

Professional full-automatic tube laser cutting machine (1500- 4000W)

R5 II is 20% smaller in size than same-grade models and easily operated in a crowded workshop, helping to make the utmost of the workshop.

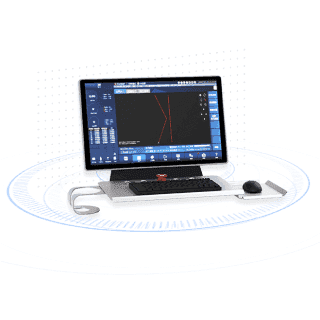

X9000, based on the German CNC bus control system, is compatible with conventional tubes and various profiles. With rich auxiliary functions, such as tube error detection and welds check, X9000 can make laser cutting simple, automatic and intelligent.

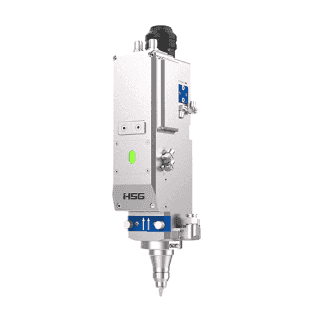

KLINGE, made of stainless steel, has a function of water cooling, dual-path cooling nozzle, ceramic ring, double focusing protective lens, drawer-type pluggable protective lens, focusing and collimating lens for long service life.

Automatic centering, 3 times faster than electric chucks

Large and constant clamping force for clamping heavy tubes

Expand clamping range of square tubes

Detecting sensor for front and rear chuck opening & clamping

Convey finished heavy tubes stably from high to low while unloading and protect tubes from any possible harm and scratch

Reduce labor intensity, save labor force and make cutting efficient

| Technical Parameters | R5 II |

|---|---|

| Power | 1500-4000W |

| X/Y-axis Positioning Accuracy | ±0.3mm/m |

| X/Y-axis Repositioning Accuracy | ±0.3mm |

| Max. No-load Speed | 100m/min |

| Max. Acceleration | 1.0G |

| Max. Rotating Speed of Chucks | 100r/min |

| Round Tube Processing Dim | Φ20-Φ240mm |

| Square Tube Processing Dim | 20*20-240*240mm |

| Max. Length of Tube | 6500mm |

| Max. Weight of Single Tube | 200kg |

| Min. Tailing | 85mm |

| Overall Dimensions (L*W*H) | 11979*4600*2350mm |