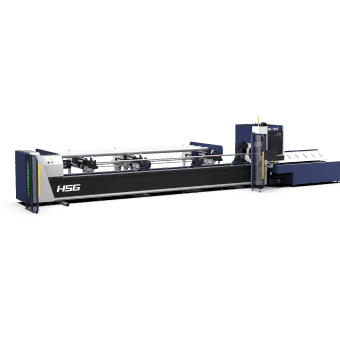

TS65II Series

Ultra-high speed tube laser cutting machine (1500-4000W)

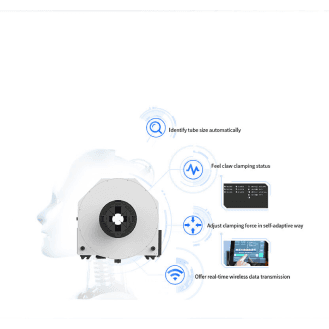

- Intelligent Digital Chucks

- HSG-X9000 Bus CNS System

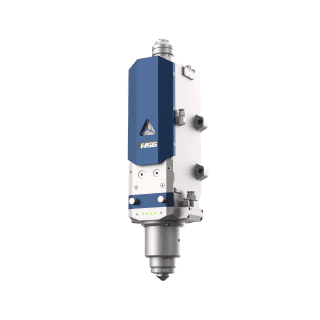

- Flying cutting, Space Leapfrog

- Cut special-shaped tubes

Ultra-high speed tube laser cutting machine (1500-4000W)

TS65 II can not only cut conventional tubes like round, square and rectangular tubes, and profiles like channel, angle and H-shaped steels, but also cut special-shaped tubes easily like triangular, concave, L and C-shaped tubes, etc.

Thanks to the imported high-torque servo motor, TS65 II can run at 120r/min rotating speed, 1.2G acceleration and reach full throttle in the blink of an eye.

It is unnecessary to change claws while clamping 10-200mm tubes. The minimum tailing is 130mm. Due to active safety measures, TS65 II will stop automatically if no or wrong tube is clamped.

XMT, as our sixth generation tube cutting system and the first multi-touch tube cutting system in China, can make operating industrial equipment as easy as playing with a tablet.

The industry’s unique technologies, namely, tube cross-plane space leapfrog and flying cutting (patent No. ZL201810158585.8), simplify the moving route of cutting head to the extreme, with no repeated lift or fall, therefore, its efficiency will be improved by 50%+ especially while cutting square tubes.

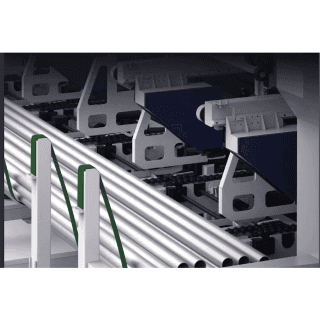

With high annealing, the machine bed will be unlikely to deform and last for a longer time. Its concave support frame can help to prevent tube swing and any possible collision between tubes and chucks. Standard Accessories:Safety light curtain: halt the machine instantly while detecting any intruder to protect machine and workers. Options and Accessories :Technology of seams detection: identify weld surface automatically with HD camera and imaging software before working;Laser-proof glass: protect workers’ retina well.

Unloading height can be adjusted by users to satisfy unloading demands of different kinds of tubes. Options and Accessories : Follow-up loading device: make unloading efficient and protect tubes from scratch; Full-/semi-automatic loading device: reduce labour intensity, save labour force and improve production efficiency

| Feature/Model | TS65 II |

| Round Tube Processing Dim. | Φ12-Φ273mm |

| Square Tube Processing Dim. | 12*12mm-200*200mm |

| Rectangle Tube Processing Dim. | Side length:12-200mm |

| Max Single Tube Loading Weight | 200kg |

| Max Bundle Loading Weight | 3000kg |

| Chuck Rotating Speed | 120r/min |

| Max. Length of Cutting Tube | 6500mm |

| Max. Moving Speed | 120m/min |

| Max. Acc. Speed | 1.2G |

| Laser Power | 1500W~4000W |

| Overall Dimensions (L*W*H) | 12400×3100×2500mm |