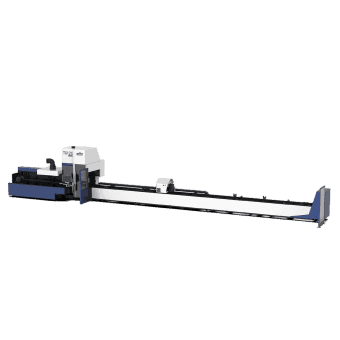

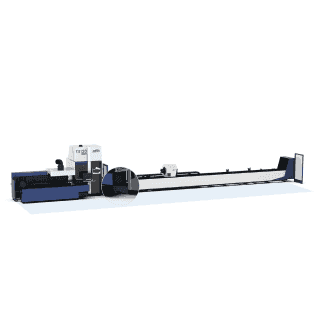

TX Plus II Series

Heavy duty tube laser cutting machine (3000-6000W)

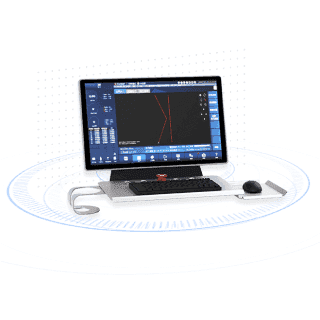

- HSG-X9000 Bus CNC System

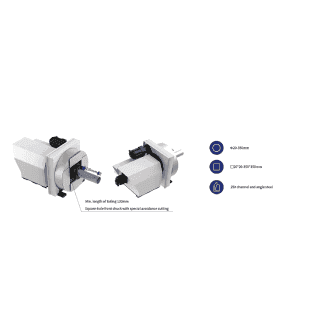

- Unique squircle pneumatic chucks

- Cut both 350mm round & square tubes

- Min. length of tailing 130mm

Heavy duty tube laser cutting machine (3000-6000W)

TX PLUS II is the first to use our unique squircle pneumatic chucks that can expand the clamping range of round and square tubes. Due to its large clamping force, heavy tubes are also easily clamped.

X9000, based on the German CNC bus control system, has rich auxiliary functions, such as tube error detection and welds check, making laser cutting simple, automatic and intelligent.

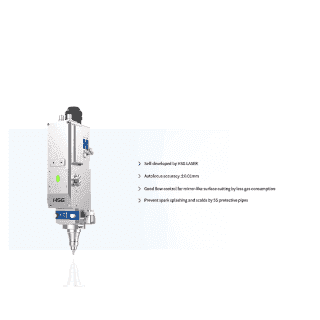

The cutting head, made of stainless steel, has a function of water cooling, dual-path cooling nozzle, ceramic ring, double focusing protective lens, drawer-type pluggable protective lens, focusing and collimating lens for long service life.

The unloading device, made of concave wheels and turning plates, is especially suitable for heavy, large and long tubes and can keep these tubes stable while unloading. Meanwhile, chuck claws will be well protected.

The ventilation opening of the front chuck is enlarged to 300mm to bring good ventilating effects in combination with high-power exhaust fan. Moreover, due to the large dust removal area in the cutting region, cutting smoke can be discharged instantly.

| Feature/Model | TX120 PLUS II |

|---|---|

| Round Tube Processing Dim | Φ20-Φ350mm |

| Square Tube Processing Dim | 20*20mm-350*350mm |

| Rectangle Tube Processing Dim | ≤350mm |

| Max. Single Tube Loading Weight | 500kg |

| Chuck Rotating Speed | 80r/min |

| Max. Bundle Loading Weight | 3000kg |

| Chuck Type | Penumatic chuck |

| Max. Moving Speed | 80m/min |

| Max. Acceleration Speed | 0.6G |

| Max. Length of Cutting Tube | 12000mm |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Laser Power | 3000-6000W |

| Overall Dimensions (L*W*H) | 18100×3500×2900mm |