BMB

Flanging Machine

Purchase probably best flanger in the marketing!

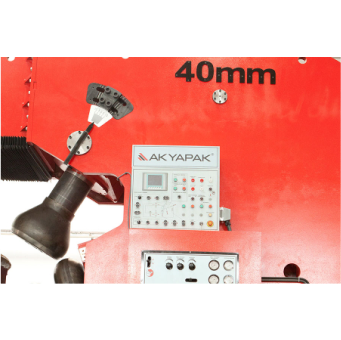

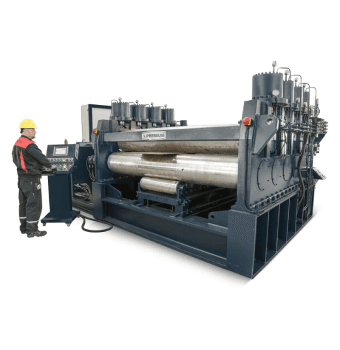

Akyapak flanging machines are designed for speed and burn to run. It is accurately engineered for lowest vibration during flanging and robustness.

The whole consturctions is electro-welded and stress relieved.Fully hydraulic control and proportional valves are for accurate setting during the flanging so it is simply operated even by new operator who doesn’t have any experience on metal forming.

It is protected against wrong setting and overload by very special hydraulic system engineered. Automatic flanging function (optional) available to flange in shortest time without taking care the material thining. Diameter range 500 – 10.000 mm.

Thickness range 2 – 50 mm (cold), 100mm hot!

With or without center hole available

You may require producing the bottom with or without center hole. Both are available in our range.

Would you like to flange very thin material?

With or without center hole, thin or thick, stainless or mild steel… Don’t worry, BMB will flange all of them material-friendly operation and lowest surface roughness.The correct capacity of model is being choosed based on the material thickness, quality and plate diameter like BMB-P.

Customer focus is our priority

Since the investment cost is always one of the important parameter to invest, AKYAPAK decided to focus on function in priority.The standard dishing press and flanging machines are designed only for basic customer needs. You don’t need to think about what is really needed or not since our experts will assist you to create right machine configuration. OR, Specify your application and send us so we will offer an appropriate solution

It is designed to produce pressure vessel, navy, nuclear, food, power generation, petrochemical, shipyard industries.

Lowest vibration during flanging

The whole machine is engineered to give lowest vibration during flanging. This is one of the main expectation and a benchmark to compare with the others.The high vibration leads to short life-time break or wearing on many components of the machine.

The components are choosen best quality for low maintenance after long life-time.Many design features, to avoid operator error, safety and aspect well engineered.

Skilled Operator is not an issue anymore

Since the flanging operation seems difficult compare to other metal forming, you are right to be afraid.

Thanks to special automation and user friend interface to get rid of this issue.It is very easy to learn and operate for any unskilled operator now. Very easy to control, high accuracy and repetation on the cycles.

- The frame of the machine is made by high alloy steel and MIG welded. The frame is also stress releived to process to have tighter tolerances after welding operation

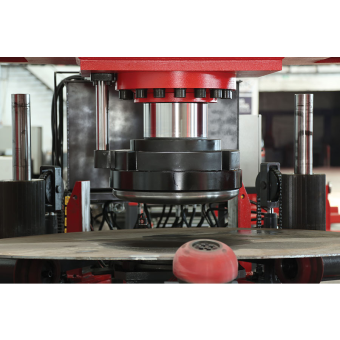

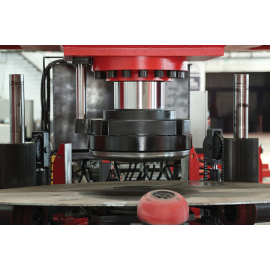

- Both upper and lower head holders driven by hydraulic motors and hydraulic cylinders

- Knuckle roll is driven by radial piston hydraulic motor for high speed rotation and torque

- Flanging roll is driven by 3 cylinders for vertical and horizontal direction and slides between two main bodies

- The dies are made of special steel with heat-treated

- A special primer applicated on all body before painting for a long term corrosion resistance

- Centralized lubrication system by hand pump operation

- Lower supporting rolls are powered by hydraulic cylinders to support the head during flanging

- Hydraulic system consists of pump with radial piston, level and temperature gauge of oil tank, filter with impurity indicator

Photo Gallery

Request Detail Information

Please fill out the requested information and you will be contacted soon.

Fill out the form to get a free consultation.