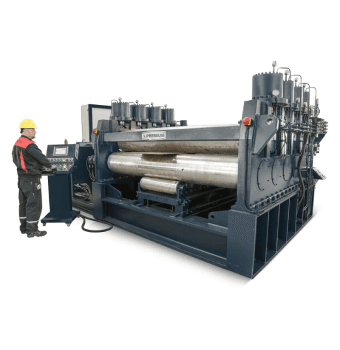

HCB – MCB – EHCB

Column Boom Systems

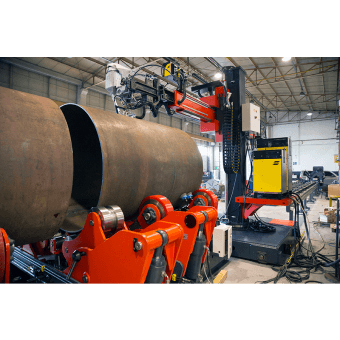

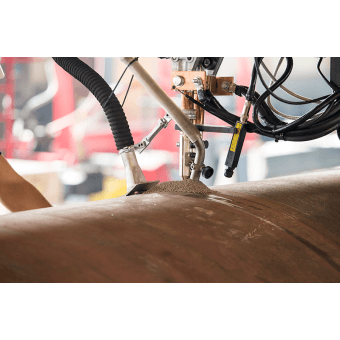

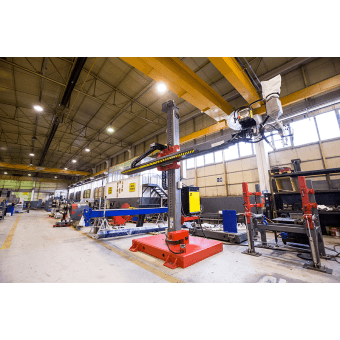

While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Column-Boom systems enables improvement of quality, reduction of manufacturing time and operator fatigue, precision and continuous welding quantity that can be realized by an operator.

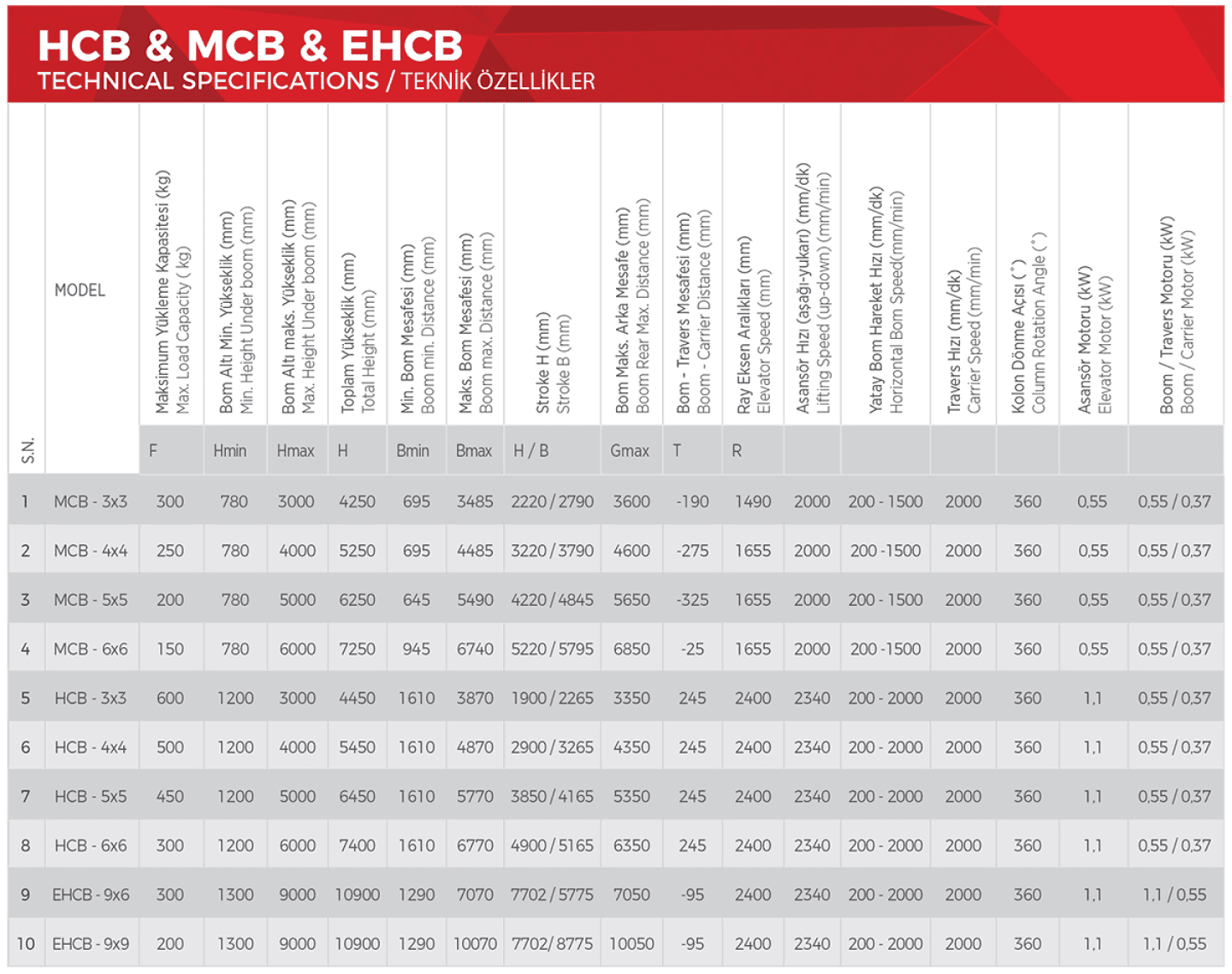

Akyapak Makine includes 3×3 to 9×9 Column-Boom systems in its standard lists. However, custom production can be realized up to 10 x 10 meters..

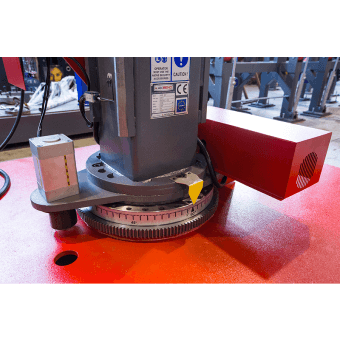

- 359° Rotatable column (manual)

- Mobile cabled controller

- V type slide system for spaceless working

- Adjustable linear Boom speed

- Boom speed digital indicator

- Setting for Boom speed (fast/slow)

- Mechanical locking system for Boom fall

- Counter weight system for Boom (Elevator)

- Limit switch on all movements

- Welding power unit’s table (above the column)

- Motors with break

- Cable channels on Column – Boom

- Fixed on the floor system

- Travelling Carrier

- Master Control Panel

- Auto Rotation Column

- Operator Seat (With Stair, only with HCB&EHCB)

- Camera Monitoring System

- Tandem Welding Apparatus

- Lighting

- Stair

- Rotators PLC Control

- Oscillator System (only MIG/MAG)

- Rail (only with Travelling Carrier)

- SAW, MIG/MAG or TIG Weldings

- Joint Tracking System – Laser

- Joint Tracking System – Mechanical Sensor

- Flux Drying Systems (only SAW)

- Mobile Control Panel

- Automation Systems

- Special Isolations For Hazardous Environment

- Tandem Welding Heads (SAW)

- Twin Welding Heads (SAW)

- Twin Tandem Welding Heads (SAW)

- AC/DC Single Power Source (SAW)

Photo Gallery

Request Detail Information

Please fill out the requested information and you will be contacted soon.

Fill out the form to get a free consultation.