Revolutionizing Production Efficiency with

ReTenX

Unlock Advanced Nesting Technology for Seamless Cutting Operations

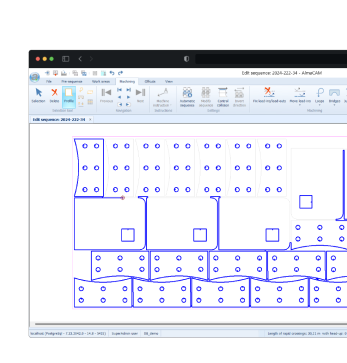

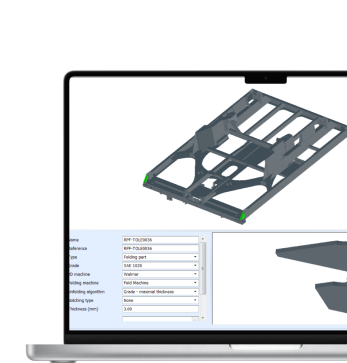

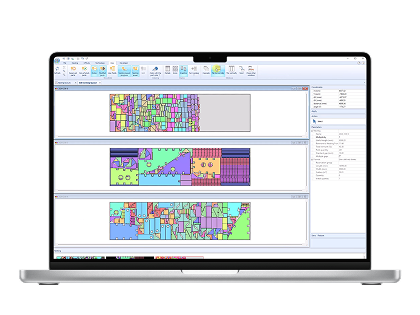

Advanced 2D CAD/CAM tools

for designing, nesting and generating cutting programs

Supports all brands of 2D cutting machines

Laser Technologies Pvt Ltd is excited to announce the launch of ReTenX, a state-of-the-art nesting software developed in collaboration with AlmaCAM, a global leader in CAD/CAM and nesting solutions. With over 45 years of expertise, AlmaCAM brings its legacy of innovation to this new software, designed to transform production workflows across industries. ReTenX optimizes raw material usage, improves sheet metal estimation accuracy, and enhances continuous laser cutting processes, making it the go-to solution for manufacturers aiming to improve efficiency and reduce waste.

Suitable for Following Product Categories

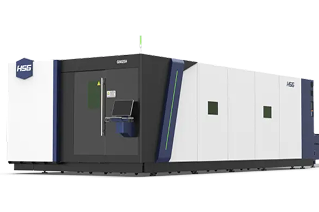

HSG Sheet & Tube Laser Cutting Machine

HSG Sheet Laser Metal Cutting Machine

HSG Sheet & Tube Laser Cutting Machine

Return on Investment (ROI)

ReTenX offers unparalleled ROI, driving cost savings and operational efficiency for manufacturers.

10X Return in 1 Year

By optimizing material usage, reducing scrap, and speeding up production cycles, manufacturers typically see a 10X return on investment within the first year.

Cost Savings

With enhanced quoting, reduced material waste, and efficient use of cutting technologies, ReTenX significantly lowers overall production costs.

Faster Production Cycles

Streamlined workflows and more accurate cost estimation reduce the time needed to complete projects, enabling manufacturers to increase output and meet customer demands more quickly.

Scalable Solutions

ReTenX is designed to grow with your business, providing flexible and adaptable solutions that scale with your manufacturing needs.

What our customers say

“RetenX has been a game-changer for us at Chris Metal Works. In just one month, we’ve saved 8.2 metric tons of material worth ₹5-6 lakh and cut down on manpower by 2 hours daily. The ROI is impressive, and I highly recommend it for anyone in sheet metal fabrication.”

Request a Demo Now!

Thank you for filling the form. We'll get back to you shortly.