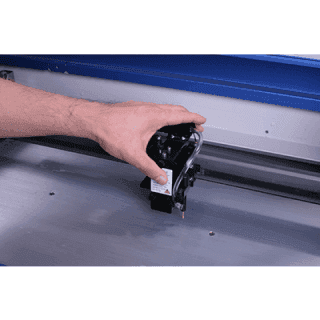

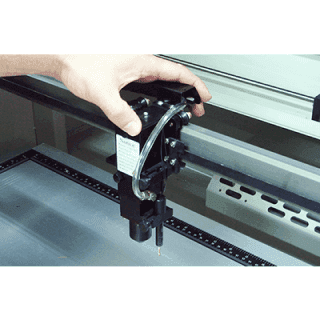

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage of the laser engraver to the desired position to be engraved and press the start button to commence the job.

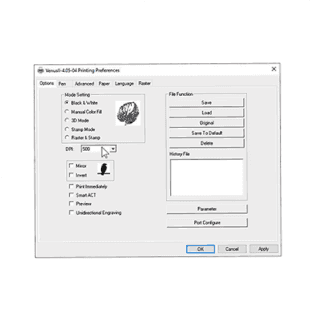

Directly output from familiar designing software like Illustrator, CorelDraw, and AutoCad through GCC LaserPro Windows driver for laser engravers. The innovative driver features SmartCENTER, Air Assist by Pen, Defous by Pen, Bridge Cutting, Drill, Dithering Patterns, and more to reduce set-up time and make easy adjustments to achieve marvellous output quality.

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using a network connection. Free your designers with great flexibility and maximum machine versatility.

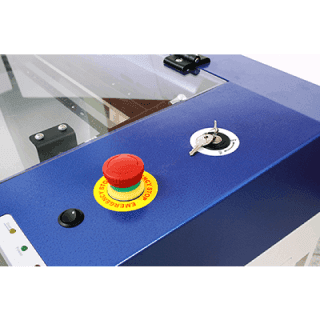

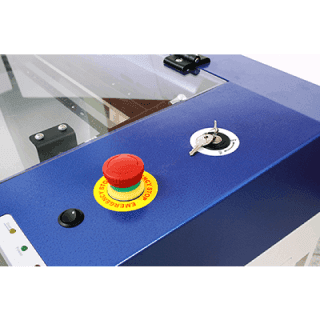

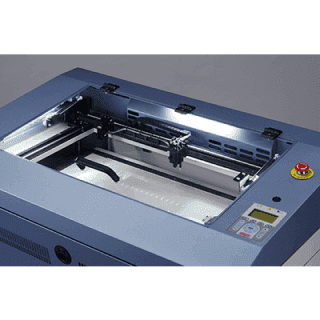

The key switch safeguards the laser engraver from unauthorized use. The prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

GCC LaserPro integrates laser firing control and image processing technology to create a 3D laser engraving function, the laser system assigns up to different laser powers to 200 levels of grayscale in the image to make spectacular 3D effects with different slopes.

The patented TrueImage function employs a uniquely designed laser firing algorithm that presents its most vivid form when laser engraving images.

Spirit laser engraver SmartACT™ is a groundbreaking technology that reduces the ramping process and job running time for laser engraving, which translates into higher productivity.

All GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (PB-free). GCC will continue to provide eco-friendly products to protect the earth for future generations.

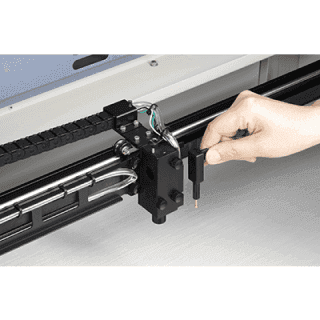

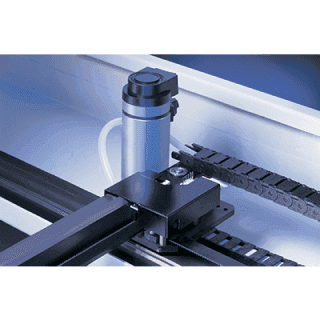

The plug-and-play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality even when laser engraving on transparent materials.

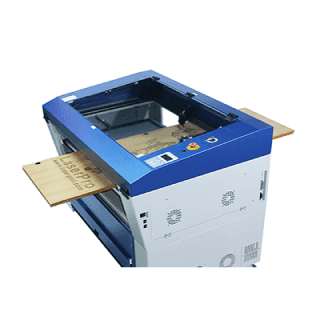

A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

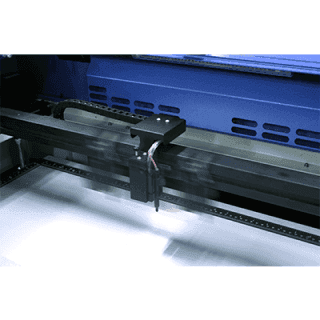

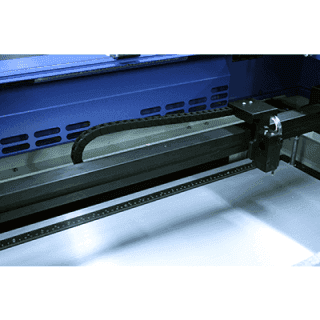

Systematic and reliable motion system embedded with a strong mechanical framework and accurate servo motor control technology to deliver superb laser engraving output quality under rapid movement.

A Built-in LED light module illuminates the working space of the laser engraver and makes every laser engraving detail easy to see.

A user-friendly menu-driven interface system simplifies the operation of the Spirit series laser engraver. Hot keys design and job status display facilitate your work and make it clear and easy to carry out.

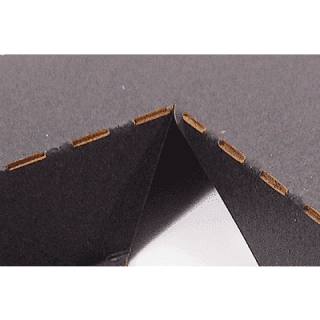

The rigid and stable chassis construction of the laser engraver ensures consistent output quality under high-speed movement.

Easy-to-use multiple position modes allow the operators an effortless way to set up laser engraving jobs with Drag-N-Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

An innovative lid that opens from both ends of the laser engraver allows easy access for daily maintenance.

Spirit laser engraver utilizes a Closed-loop DC servo motor that delivers greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy for laser engraving due to the continuous movement, instead of constant stopping and starting.

Bridge Cutting function diversifies the laser cutting into packaging prototyping and fulfils versatile requirements. Define the cutting gap to create the dashed line effect from ua ser-friendly print driver interface.

| Specification | Details |

|---|---|

| Working Area | 740 x 460 mm (29 x 18 in.) |

| Z-axis | 165 mm (6.5 in.) |

| Wattage | 12W~100W |

| Max. Working Speed | 80 IPS |