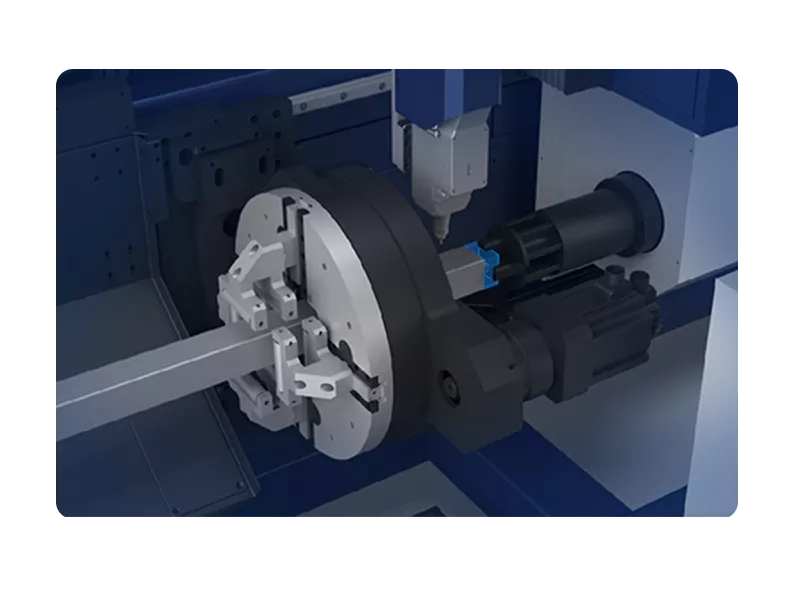

Our machine bed boasts a highly accurate, independently controlled servo follow-up support system. This provides ideal support for rotational cutting; resulting in remarkable precision and high cutting accuracy.

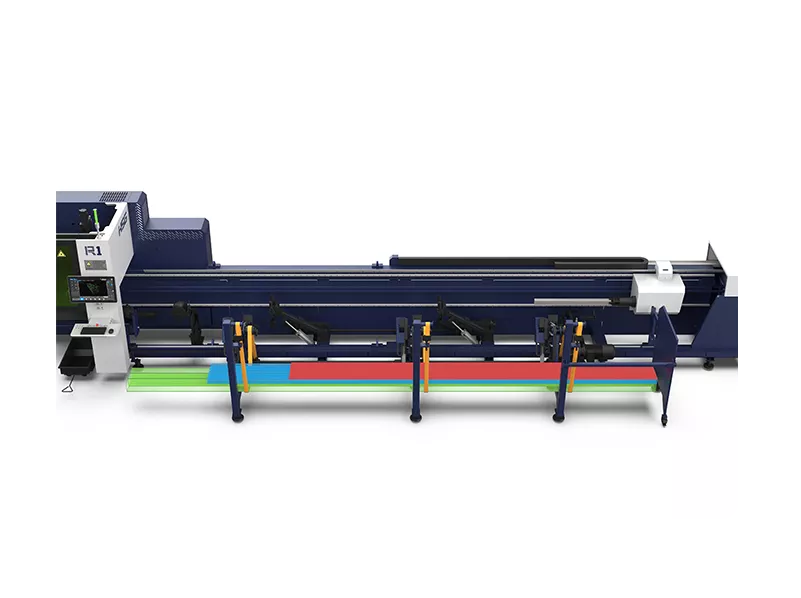

The R1 Series laser cutting machines include an automatic material rack, that can load materials in just 20 seconds. The rack can handle tubes with diameters ranging from 20mm to 120mm and lengths of 4m to 6.5m. For added flexibility, the automatic material rack also supports semi-automatic loading, allowing for one-by-one material feeding as needed.

The R1 Series machines feature an innovative chuck jumping mechanism that significantly reduces tailing lengths, even with large amplitude cuts. This combined with high-precision cutting capabilities, ensures accuracy for long tube cuts by adjusting the chuck displacement. An optional servo chuck leaping system can be fitted to increase efficiency by offering fast and precise chuck movement.

The R1 Series is designed to handle a wide range of processing demands, and it has an intelligent bus operating system with a variety of auxiliary capabilities. It includes professional nesting software, enabling efficient management of production workflows and accurate price calculations, ensuring that each project is executed with maximum efficiency and minimal waste.

| Model | Power | X/Y-axis Positioning Accuracy | Cutting Capacity of Round Tube | Cutting Capacity of Square Tube | Weight of Single Tube |

|---|---|---|---|---|---|

| R1R | 1500-3000W | ±0.05mm/m | Φ8-Φ120mm | □88-□120120mm | 80kg |

| Specifications are liable to change without prior notice. | |||||