Table of Content

- Understanding the R2 Series Tube Laser Cutter

- Key Features of the R2 Series Tube Laser Cutter

- Where can the R2 Series be Applied in Industrial Production?

- Benefits of the R2 Series Laser Cutter

- Why Choose Laser Technologies?

- Conclusion

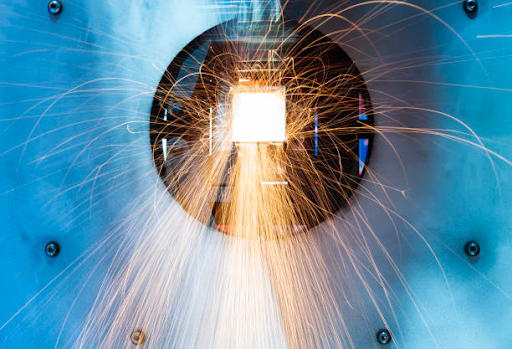

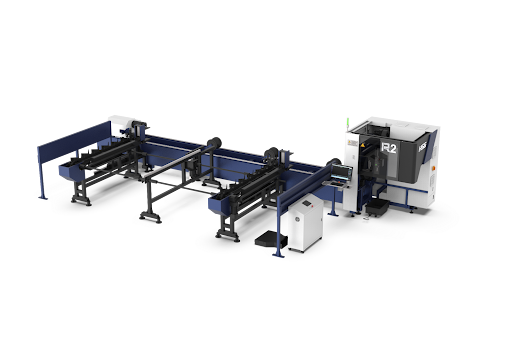

In today’s manufacturing environment, precision, efficiency, and adaptability are essential for maintaining a competitive edge. Laser Technologies, a leader in innovative laser cutting solutions, introduced the Advanced R2 Series Tube Laser Cutter, an advanced machine that redefines the possibilities in tube cutting.

Designed with features and robust engineering, the R2 Series Tube Laser Cutter is tailored to meet the needs of industries requiring accuracy, speed, and versatility. With high-precision tube cutting, the R2 Series Tube Laser Cutter is capable of handling a wide range of materials and thicknesses, making it a versatile solution for various applications.

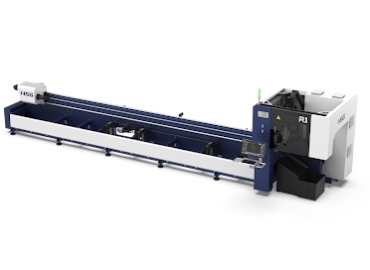

Understanding the R2 Series Tube Laser Cutter

The Advanced R2 Series Tube Laser Cutter exemplifies cutting-edge design and precision engineering. Built for the demands of modern manufacturing, it delivers seamless operation, enhanced productivity, and exceptional accuracy.

With its advanced features and user-friendly interface, the R2 Series Tube Laser Cutting Machine can easily handle a wide range of tube and profile-cutting applications. It has a two-chuck laser cutter with automated functions, making it a valuable asset for any production facility looking to streamline its operations and increase efficiency.

Key Features of the R2 Series Tube Laser Cutter

The R2 Series Tube Laser Cutter is designed to maximize efficiency and accuracy in tube-cutting applications, making it an ideal choice for industries requiring precise and complex cutting capabilities.

1. Exceptional Cutting Capacity

The R2 Series is designed to handle a wide range of tube and pipe dimensions with ease. This machine boasts a chuck operating speed of 120 m/min and a rotation speed of 100 r/min, enhancing processing times and overall efficiency.

2. HSG-X Bus Control System

What is the role of the HSG-X bus control system in tube cutting? The HSG-X bus control system, created by HSG Laser, is used by the R2 series. This clever, user-friendly technology offers practical answers to everyday problems, including complicated operations and low productivity while streamlining processes, cutting down on inefficiencies, and lowering expenses.

3. Automatic Loading and Unloading System

Efficiency is at the heart of the R2 Series. Its fully automatic loading and unloading system streamlines operations, reducing manual intervention and downtime. This feature is particularly beneficial for high-volume production lines, enabling continuous processing and improved productivity.

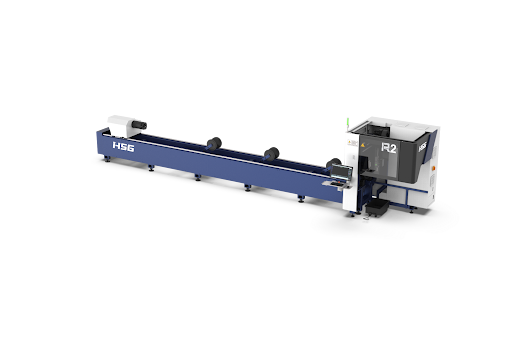

4. Versatile Rectangular-Circle Chucks for Various Tubes

The R2 series supports tubes up to 300 kg with rectangular-circle chucks, accommodating various tube types like round, square, and angle steel. Specialized chucks can be fitted for enhanced sealing and protection.

5. Double-chuck Universal Tube Laser Cutting Machine

What are the benefits of a two-chuck tube laser cutter? A two-chuck tube laser cutter allows for simultaneous loading and unloading of materials, increasing productivity and reducing downtime. This feature also enables the machine to handle a wider range of tube sizes and shapes, providing greater flexibility in production processes.

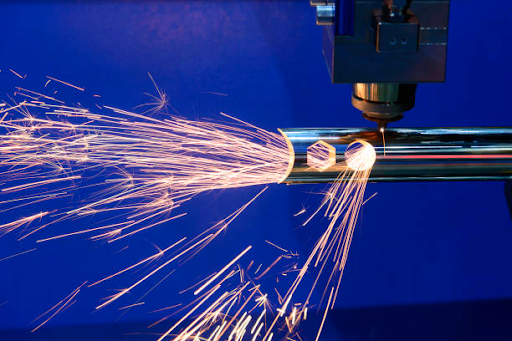

6. Advanced Tube Cutting Machines With Environmental Focus

The R2 Series Features Advanced Tube Cutting capabilities, allowing for precise and efficient cutting of various tube materials. Additionally, the machine is designed with an environmental focus, incorporating energy-saving features to reduce waste and promote sustainability in manufacturing processes.

When should you upgrade to an advanced tube laser-cutting machine? Upgrade to an advanced tube laser cutting machine like the R2 Series when you are ready to take your manufacturing operations to the next level. Experience increased productivity, improved accuracy, and laser cutting efficiency.

Where can the R2 Series be Applied in Industrial Production?

The Advanced R2 Series Tube Laser Cutter is a breakthrough for industries where precision and efficiency are critical. Here are some key sectors that benefit from its advanced capabilities:

1. Automotive Industry

From exhaust systems to chassis components, the automotive sector demands precision cutting for various tube and pipe applications. The R2 Series delivers high-quality cuts that meet stringent industry standards, ensuring reliability and safety.

2. Furniture Manufacturing

Modern furniture design often incorporates tubular structures for aesthetics and functionality. The R2 Series enables manufacturers to create intricate designs with clean, burr-free edges, enhancing the overall product quality.

3. Aerospace Industry

Precision is paramount in aerospace manufacturing. The R2 Series excels in producing complex components with tight tolerances, making it an indispensable tool for this sector.

4. Construction and Architecture

Architectural designs and construction projects often involve customized tube and pipe structures. The R2 Series supports innovative designs with its ability to cut intricate patterns and shapes effortlessly.

Benefits of the R2 Series Laser Cutter

Investing in the R2 Series Tube Laser Cutter offers a host of benefits, including:

1. Enhanced Productivity

The automatic loading and unloading system, combined with high-speed cutting capabilities, significantly reduces idle time, boosting overall productivity.

2. Superior Precision

How does the R2 Series achieve high precision and efficiency? The advanced R2 series tube laser cutter utilizes technology such as real-time monitoring and automatic correction features to ensure precise and accurate cuts every time. Additionally, its streamlined design minimizes material waste, further enhancing efficiency and cost-effectiveness.

3. Ease of Operation

The intuitive control interface and user-friendly software make the R2 Series accessible to operators of all skill levels, reducing training time and improving efficiency.

4. Durability and Reliability

Engineered with high-quality components, the R2 Series offers long-term durability and reliable performance, even under demanding conditions.

Why Choose Laser Technologies?

Laser Technologies stands out as a trusted partner in laser cutting solutions. Here’s why manufacturers worldwide choose us:

1. Proven Expertise

With years of experience in laser technology, we deliver innovative solutions tailored to the evolving needs of modern industries.

2. Customer-Centric Approach

Our commitment to customer satisfaction drives us to provide high-quality products and exceptional support. From pre-sales consultation to after-sales service, we ensure a seamless experience.

3. Complete After-Sales Support

Our relationship with customers extends beyond the purchase. We offer:

- On-site installation and training

- Regular maintenance services

- Technical support and troubleshooting

Access to genuine spare parts and upgrades This comprehensive support ensures optimal performance and longevity of your investment.

4. Innovation and Quality

At Laser Technologies, innovation and quality go hand in hand. The R2 Series demonstrates our commitment to providing innovative solutions that enable manufacturers to maintain a competitive edge.

Conclusion

The Advanced R2 Series Tube Laser Cutter by Laser Technologies is more than a machine; it’s a catalyst for precision, efficiency, and innovation. Its advanced features, robust performance, and user-friendly design make it an invaluable asset for industries ranging from automotive to aerospace.

The R2 Series is the best tube laser-cutting machine in the market. Partner with Laser Technologies to experience the future of tube and pipe cutting and unlock new possibilities for your manufacturing operations. Transform your production capabilities with the R2 Series, where precision meets excellence.