Table of Content

- Best Laser Welding Machines in 2025

- Why Choose Laser Technologies for Your Laser Welding Needs?

- Conclusion

- FAQ

Laser welding machines in India are constantly evolving to meet the growing demands of manufacturing. Whether working on small or large industrial projects, you can buy laser welding machines from Laser Technologies in India.

Here is the list of the best laser welding machines in 2025, offering efficiency, reduced costs, and the best weld quality.

Best Laser Welding Machines To Look for 2025

Let’s explore the Best Laser Welding Machines in 2025 that offer advanced features and precision welding.

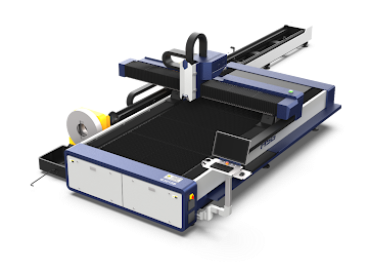

1. Air-cooled handheld Laser Welding Machine

An Air-cooled Handheld Laser Welding Machine is one of the top choices for industries looking for a compact, portable, and cost-effective laser welding solution.

Key Features:

- Portability: The handheld design allows operators to manoeuvre the machine easily, making it perfect for welding in tight spaces or on-site applications. It is lightweight and has 24 preset modes.

- Air Cooling: Unlike many traditional laser welding machines that rely on liquid cooling systems, this model uses air cooling. This feature is advantageous for areas where water access is limited or where the presence of water could cause additional issues.

- High Power Output: Despite its compact size, the air-cooled handheld laser welding machine delivers impressive welding power, ensuring high-quality welds on various metals.

The air-cooled handheld laser welding machine from LTPL is an excellent choice for industries looking to streamline their welding processes without compromising on quality. Its portability and low-maintenance design make it suitable for both small workshops and large-scale industrial applications.

Also Read, How To Find Perfect Laser Welding Machine

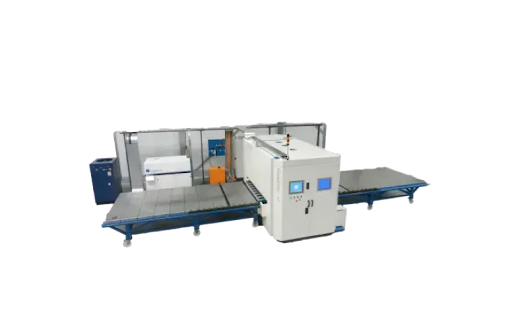

2. Smartweld: Cost-Effective Laser Welding System

The Smartweld system by Laser Technologies is one of the best choices in the market. This welding machine is designed to offer high-performance laser welding, making it ideal for businesses that need to stay within budget while maintaining high-quality welds.

Key Features:

- Ease of Use: The ergonomic design makes it easy for operators to perform laser welding tasks. The user-friendly interface and controls ensure that workers can operate the machine with minimal training.

- Wide Range of Applications: Smartweld is designed to handle a variety of metals. This versatility makes it ideal for industries ranging from automotive and aerospace to electronics and construction.

- Faster Writing Speed: The writing speed is 2-10 times faster than traditional methods, resulting in the saving of at least 2 welders annually.

Smartweld is an excellent option for companies that need a cost-effective laser welding machine without compromising on performance. With its robust features and user-friendly design, it allows factories to perform high-quality welds.

Read More, Top 7 Tips To Maintain Your Laser Welding Machine

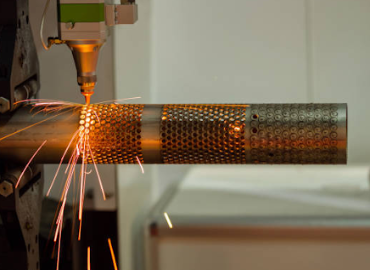

3. Pillow Plate Laser Welding Machine

For industries that require welding specialized surfaces, the Pillow Plate Laser Welding Machine is the best choice. This machine is designed for complex systems like heat exchangers, reactors, and other industrial equipment that require durable welding.

Key Features:

- Precision Welding: The Pillow Plate Laser Welding Machine provides high-precision welds, which are essential for ensuring the integrity of the pillow plate, especially when used in high-pressure or high-temperature applications.

- High-Speed Welding: This machine can achieve high welding speeds with weld quality. It is optimized to reduce processing time, allowing manufacturers to achieve faster turnaround times and higher productivity.

- Energy Efficient: Laser welding technology is inherently more energy-efficient than traditional welding methods, which reduces operational costs and contributes to a more sustainable manufacturing process.

- Customizable: They offer customizable features based on the specific needs of customers.

The Pillow Plate Laser Welding Machine ensures welds are not deep and are made with low heat input, which prevents the overheating of the material. With this, even the inner surface of the jacket retains its initial shape after welding.

The cooling medium's through-flow improves the cooling effect, and the pillow plate surface can also be easily adjusted to various connectors on the jacket tank without losing its cooling surface.

Read More, 5 Applications of Laser Welding in Industries

Why Choose Laser Technologies for Your Laser Welding Needs?

It has established itself as a leading provider of advanced laser welding solutions, offering a wide range of machines designed to meet the diverse needs of modern industries. Here’s why Laser Technologies could be one of the ideal laser welding machine suppliers near me.

1. Proven Expertise and Innovation

It boasts years of experience in this field, pushing the boundaries of innovation to develop welding machines that integrate with the latest technological advancements. Their focus on continuous improvement ensures that customers receive cutting-edge products designed for optimal performance.

2. Quality and Reliability

When you choose a laser welding machine from LTPL, you are investing in a product that prioritizes quality. Each machine undergoes stringent testing and quality control procedures to ensure that it delivers consistent, high-quality results with every use.

3. Comprehensive Customer Support

They don’t just sell machines; they offer ongoing support to ensure that you get the most out of your equipment. From installation and training to maintenance and repairs, their customer support team is always ready to assist you, ensuring minimal downtime and maximum productivity.

4. Tailored Solutions

They understand that every business has unique needs. That’s why they offer customized solutions that fit your specific requirements, whether you need special features for a niche application or custom configurations for your welding projects.

Conclusion

The demand for efficiency and cost-effectiveness in welding continues to grow. Laser welding machine from Laser Technologies meets all the industry demands. Whether you want a portable, handheld welding system or a pillow plate welding machine Laser Technologies has them all. Book your demo today and find your ideal laser welding machine near me.

By investing in a laser welding machine from Laser Technologies, you can expect top-notch performance, reliability, and support, helping your business stay ahead. Choose from the best laser welding machines in 2025 for your next laser welding investment and experience the future of welding technology.

FAQs

1. Is it worth buying a laser welding machine?

Ans: Yes, it is definitely worth buying a laser welding machine. Investing in a laser welding machine offers high-precision, quality welds, faster speed, minimal post-weld treatment, lower operational costs, and easy integration into automated production lines.

2. How much does a decent laser welding machine cost?

Ans: The cost of a laser welding machine can vary depending on several factors, including the machine’s specifications, capabilities, and features. On average, a decent laser welding machine can cost anywhere from Rs 8,00,000 to Rs 85,00,000 or more.

3. What are the benefits of choosing a handheld laser welding machine?

Ans: Handheld laser welding machines offer portability, ease of use, less maintenance, and versatility in applications. They are user-friendly and suitable for both experienced and beginner users.