Table of Content

- Applications of Fiber Laser Cutting

- Why Choose Laser Technologies for Your Fiber Laser Cutting Needs?

- Conclusion

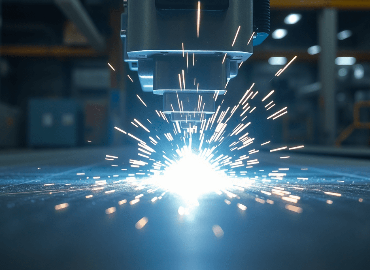

Efficiency is a crucial factor in modern manufacturing. Among the various technologies revolutionizing industrial processes, fiber laser cutting is one of the most cost-effective solutions. Applications of fiber laser cutting span a wide range of industries.

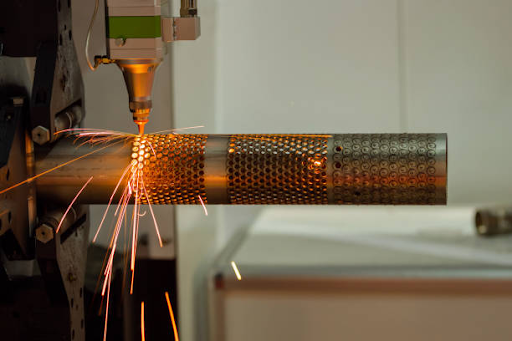

What is a fiber laser cutting machine? A fiber laser cutting machine is a type of industrial cutting tool that uses a fiber laser to cut materials, typically metals, with high precision and efficiency. Fiber laser cutting machines use high-powered lasers to produce clean, precise cuts. The "fiber" part refers to the laser's light source, which is generated in a fiber optic cable, unlike older CO2 lasers.

Applications of Fiber Laser Cutting

Fiber laser machines have gained more prominence over the years due to their performance. In this article, we will understand the top 9 industrial applications of fiber laser cutting and how these machines, like those supplied by Laser Technologies, transform the industry.

1. Metal Fabrication

Metal fabrication is one of the most widespread applications for the Fiber Laser Cutter. The metal processing machine applications range from cutting intricate designs to mass production of components. These systems reduce material waste and improve cutting speeds, making them highly efficient for various metal processing needs.

The fiber laser cutter utilizes a focused beam of light to melt and vaporize metal, achieving cuts that are sharp and highly precise. This capability is crucial for industries requiring detailed, complex designs or tight tolerances, such as HVAC systems or precision mechanical parts.

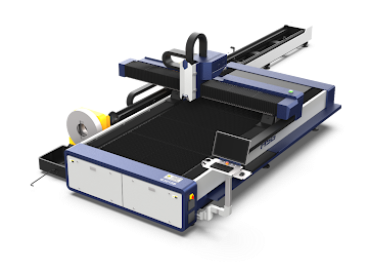

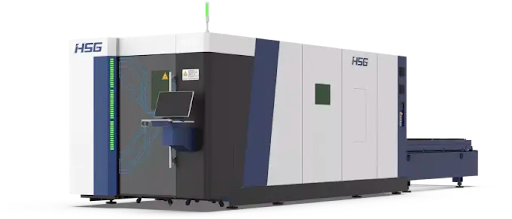

Laser Technologies offers cutting-edge fiber laser machines, such as the GX Series Double Exchange Platform Laser Cutting Machine, designed specifically for high-volume production. The new algorithm offers intelligent path optimization, smart vibration control, torque protection for dual drives, and DA correction of air pressure.

2. Automotive Industry

The automotive industry is another major player benefiting from fiber optic laser cutting. Laser cutting allows automotive manufacturers to produce high-precision components, from intricate body panels to structural parts. The new fiber laser cutting machines are highly valued for their ability to handle various materials, including thick steel plates used in automotive manufacturing.

The precision of fiber laser cutting allows manufacturers to produce complex shapes, such as contoured body panels, with minimal distortion or material wastage. Laser cutters are integrated with automated systems to enable high-speed cutting of multiple parts simultaneously. The accuracy of the cuts ensures that automotive parts fit together perfectly during assembly, reducing the need for further adjustments and ensuring product quality.

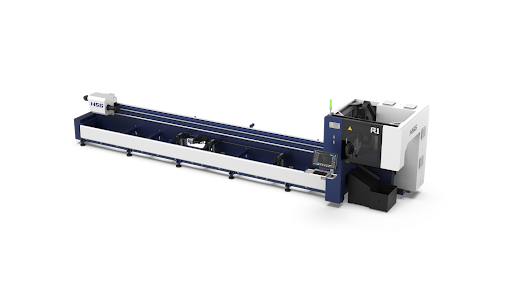

The R1 Series Laser Cutting Machines feature an advanced support system for precision cutting, an automatic material rack for efficient multi-mode material loading, and innovative chuck-jumping technology for minimal tailings. They are suitable for automotive parts manufacture and industrial metalworking applications.

3. Aerospace Industry

The aerospace sector demands the highest standards of precision and reliability. Fiber laser cutting machine applications play a crucial role in the fabrication of aerospace components such as wing structures, fuselage parts, and engine components. The technology enables manufacturers to cut complex geometries with minimal material distortion, ensuring that each piece meets rigorous safety and performance specifications.

Components in aerospace manufacturing, such as wing structures, fuselage parts, engine components, and turbine blades, require extremely precise cutting due to their complex shapes and material properties.

4. Electronics Manufacturing

In electronics, every component must fit perfectly within tight tolerances. Industrial fiber laser cutting machines are used extensively in the manufacturing of printed circuit boards (PCBs), connectors, heat sinks, and other tiny components. Laser cutting allows for the high-speed and accurate production of small, intricate parts without the risk of material deformation or damage.

For instance, laser cutting is often used to cut precise patterns and shapes on PCBs or to make micro-cuts in materials like thin aluminum. The fiber lasers can cut without damaging the sensitive components; it is greatly minimized.

Laser Technologies offers the Best Fiber Laser-cutting Machine that meets the needs of electronics manufacturers. Their machines are designed to produce burr-free, precise cuts, ensuring that every component meets the high standards required in the electronics industry.

5. Medical Device Manufacturing

Medical devices require absolute precision, both in terms of design and functionality. Fiber laser cutting is ideal for this application due to its ability to cut thin, delicate materials with high accuracy. The technology is commonly used to create components for surgical instruments, implants, and diagnostic devices.

For example, it is used to create tiny, precise holes in surgical tools or to fabricate intricate geometries for implants like pacemakers or dental devices. Fiber lasers are also effective at creating smooth, burr-free cuts, which is essential in medical device manufacturing, as any rough edges could harm patients or interfere with the device’s function.

Fiber laser cutting also allows for clean, precise cuts that minimize the risk of contamination, which is essential in the medical field. Laser Technologies Fiber Laser Cutting Machines are capable of handling the demands of this industry.

Your Next Innovation Starts Here—Explore the Best Laser Cutting Machines for 2025!

6. Shipbuilding

The shipbuilding industry also leverages fiber laser cutting technology to cut through thick steel and other materials used in ship construction. Fiber lasers can easily handle the large and complex parts required in shipbuilding, including hull sections, decks, and propellers.

Fiber laser cutting is used in shipbuilding to produce large and complex components, such as hull sections, decks, and engine parts. The ability of fiber lasers to cut through thick materials with precision makes them an excellent tool for the shipbuilding industry, where large-scale, high-quality components are essential.

Laser Technologies supports the shipbuilding industry with high-powered fiber laser systems that can cut through tough materials with ease.

7. Signage and Decorative Panels

Beyond industrial manufacturing, fiber laser cutting is also widely used in the production of signage and decorative panels. The technology allows businesses to create customized, intricate designs for signs, logos, and art pieces, all while ensuring a high-quality finish. Laser cutting is used for cutting a logo, engraving patterns, or creating custom art pieces for decoration. The fiber laser cutters offer the best designs.

Applications of lasers in industry are seen as they produce fine and smooth edges without the need for post-processing. Laser Technologies provides high-precision fiber laser machines that make this type of work easy and efficient, offering scalable solutions for both small businesses and large corporations.

Want to know more? Read our full guide on Laser Cutting Machines Price in India

8. Renewable Energy Sector

Fiber laser cutting has found significant applications in the renewable energy sector, particularly in the production of solar panels, wind turbines, and energy storage systems. The precision and efficiency of the CNC Fiber Laser Cutting Machine made it ideal for manufacturing components like thin metal sheets for photovoltaic cells, intricate turbine blades, and structural parts for battery systems.

In the production of solar panels, for instance, fiber laser cutters are used to cut thin metal sheets and photovoltaic materials, ensuring that the cuts are precise and the integrity of the cells is maintained. Laser cutting is essential in creating intricate components, such as the grids used to capture sunlight, as well as cutting the metal frames that house the solar panels. In wind energy, fiber laser cutters are used to create turbine blades, cutting complex aerodynamic shapes from materials like steel and composite fibers.

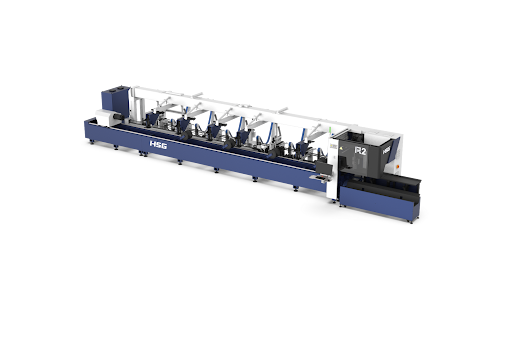

Laser Technologies provides advanced fiber laser solutions, such as the R2 Double-chuck Universal Tube Laser Machine and the R3 tube laser cutting machine, which offer high-speed, precise cutting for a variety of materials used in renewable energy applications. The machines help manufacturers meet the growing demand by enhancing production speed and reducing material waste.

9. Prototype Manufacturing

In prototype manufacturing, flexibility is the critical factor, especially when creating new products or iterating on designs. Fiber laser cutting is invaluable in prototype production, as it allows for rapid and precise cutting of various materials, including metals, plastics, and composites. Designers and engineers use laser cutting to quickly produce prototypes of new products or components for testing and validation.

The laser cutting process is ideal for prototyping because it allows for fine details to be incorporated into the design with ease, and any design changes can be easily implemented in the software controlling the laser cutter.

Also Read, A Fiber Laser Machines Price Guide In India: Understanding the Investment

Why Choose Laser Technologies for Your Fiber Laser Cutting Needs?

When it comes to selecting a fiber laser cutting machine for your business, Laser Technologies offers expertise and solutions that cater to a wide variety of industries. Here are a few reasons why Laser Technologies should be your go-to choice:

1. Precision and Innovation:

With a focus on providing high-quality fiber laser cutting machines, Laser Technologies ensures that every machine delivers precise, clean cuts, improving both the efficiency and quality of your manufacturing process.

2. Customization:

Whether you need a machine for cutting intricate electronic components or large metal panels, Laser Technologies offers customizable solutions tailored to your specific needs.

3. After-Sales Support:

Laser Technologies takes pride in offering world-class After-Sales Support. Their dedicated team provides regular maintenance, troubleshooting, and optimization services, helping you get the most out of your equipment and ensuring minimal downtime.

4. Cost-Effective Solutions:

Despite offering cutting-edge technology, Laser Technologies ensures that their machines are competitively priced, making high-performance laser cutting accessible to both small businesses and large enterprises.

Conclusion

- Fiber laser cutting technology is changing the way industries approach manufacturing. From metal fabrication to aerospace, fiber lasers offer precision, efficiency, and versatility. If you're looking for a reliable, high-performance solution for your cutting needs, then Laser Technologies is the perfect solution.

- Their fiber laser cutting machines are engineered to deliver exceptional results across a variety of industries. With a commitment to precision, customer satisfaction, and ongoing support, Laser Technologies is the partner you can trust for all your laser-cutting needs.