Table of Content

- Recent Innovations in Fiber Laser Cutting

- Benefits of Fiber Laser Cutting Technology

- New Materials and Applications

- Automation and Integration

- Environmental Impact

- Safety Enhancements

- Challenges and Limitations

- Future of Fiber Laser Cutting

- Comparison with Other Technologies

- Cost Analysis

- Conclusion

- FAQs

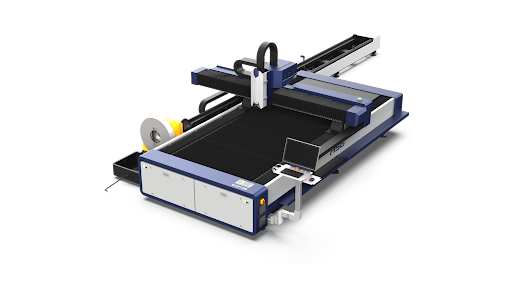

The manufacturing industry has experienced numerous technological advancements over the years, but few have been as transformative as advanced laser-cutting solutions. The latest innovations in fiber laser cutting technology are revolutionising the industry with their unparalleled precision, speed, and versatility, opening up new possibilities for manufacturers looking to stay ahead of the curve.

Recent Innovations in Fiber Laser Cutting

The last few years have seen remarkable innovations in fiber laser equipment, enhancing its capabilities and applications of fiber laser machine.

1. Advancements in Laser Power Source

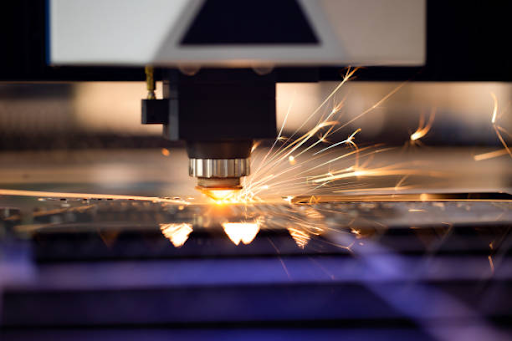

One of the most significant innovations has been the improvement of laser sources. Modern fiber lasers are more powerful and efficient due to diode technology and refined fiber optics. These lasers offer higher beam quality, which translates to smoother cuts and better overall performance.

2. Improvements in Beam Quality and Control of Laser Source

Recent developments have also focused on improving the quality and control of the laser beam. Innovations in beam shaping and modulation have allowed manufacturers to achieve more consistent results, even with challenging materials. This advancement has opened up new possibilities for complex designs and efficient laser cutting machine working.

Benefits of Fiber Laser Cutting Technology

Fiber laser cutting stands out due to several advantages, such as high precision, faster cutting speeds, and lower energy consumption compared to traditional cutting methods.

- Precision and Accuracy: The laser beam is incredibly fine and can be precisely controlled, allowing for intricate designs with laser cutting machine metal with minimal waste.

- Speed and Efficiency: fiber lasers can cut through materials at high speeds, significantly reducing production times and increasing throughput.

- Versatility in Materials: From metals like steel and aluminium to non-metallic materials such as plastics and composites, the Fiber Laser Cutting Machine are capable of cutting a wide variety of materials with ease.

Laser Technologies Pvt. Ltd. is a trusted partner for global brands like HSG, Alpha Laser, GCC, Stiefelmayer, and Rodomac, offering the best industrial laser solutions in India and specialising in fiber laser technology and laser cutting. Our team are dedicated to staying at the forefront of innovation, ensuring that our customers receive the most advanced solutions available.

New Materials and Applications

With the ability to handle a broader range of materials, Fiber Laser Cutting Machine Manufacturers in India are finding new applications in various industries.

1. Expansion into Different Materials

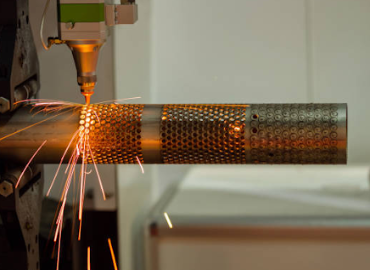

Innovations have enabled fiber lasers to cut materials previously considered unsuitable for laser cutting, such as certain alloys and composite materials. This expansion has made fiber laser technology more relevant in fields like medical device manufacturing and consumer electronics.

2. Emerging Industrial Applications

From automotive to aerospace, the adoption of fiber laser cutting is growing. Its ability to produce lightweight, high-strength components has made it a staple in industries focused on reducing weight and improving performance.

Want to know more? Read our full guide on Laser Cutter Machine Price

Automation and Integration

The rise of automation and integration with integration and other laser-cutting machine software technologies has further enhanced the capabilities of fiber laser cutting.

1. Role of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning are being used to optimize cutting processes. These technologies can predict potential issues and adjust parameters in real-time, leading to higher-quality cuts and reduced downtime.

2. Other Software Technologies

Cypcut, LightBurn, SC1000, and SigmaNEST are just a few examples of software that can be integrated with fiber laser cutting machines to optimize performance and efficiency. These software technologies offer features such as nesting, tool path optimization, and real-time monitoring to streamline the cutting process.

3. Integration with CAD/CAM Systems

Fiber laser cutters are increasingly being integrated with CAD/CAM systems, allowing for seamless design-to-production workflows. This integration reduces errors, speeds up production, and allows for greater customisation. Discover how the latest innovations in fiber laser cutting technology are revolutionising the manufacturing industry. Stay ahead of the competition with advanced solutions from Laser Technologies.

Environmental Impact

As industries strive to be more environmentally friendly, the energy efficiency of fiber lasers is a significant advantage.

- Energy Efficiency: Fiber lasers are known for their low energy consumption compared to other technologies. This efficiency not only reduces operational costs but also lowers the carbon footprint of manufacturing processes.

- Reduction in Waste: The precision of modern laser cutting innovations minimizes material waste, contributing to more sustainable production practices.

Also Read: How to Maintain a Fiber Laser Cutting Machine for Optimal Performance

Safety Enhancements

With any powerful technology, safety is a critical concern. Recent innovations have addressed this by introducing new safety features and protocols.

- Improved Safety Features: Modern fiber laser cutters come equipped with advanced safety systems, including automatic shutdowns and protective enclosures, to protect operators from potential hazards.

- Operator Training and Protocols: Manufacturers are emphasising the importance of proper training and adherence to safety protocols, ensuring that operators are well-prepared to handle the technology safely and effectively. Laser cutting technology trends are focussing on integrating artificial intelligence to further enhance safety measures and prevent accidents in the workplace.

Challenges and Limitations

Despite its many benefits, fiber laser cutting technology does face some challenges and limitations.

- Current Hurdles in Technology: Issues such as the initial cost of equipment and the need for skilled operators are among the challenges that companies must address when implementing fiber laser cutting technology.

- Potential Solutions: Innovations in training programs and government incentives could help overcome these hurdles, making the technology more accessible to a broader range of manufacturers.

Future of Fiber Laser Cutting

Looking ahead, the potential for further innovations in fiber laser cutting technology is vast.

1. Predictions and Trends

Experts predicted that fiber lasers will become even more efficient and versatile, with new applications emerging in industries such as renewable energy and biotechnology.

2. Potential for Further Innovations

Ongoing research and development efforts are likely to lead to breakthroughs in areas such as beam quality, control, and integration with other manufacturing technologies.

Comparison with Other Technologies

Understanding how fiber laser cutting stacks up against other technologies is crucial for making informed decisions.

1. Fiber Laser vs. CO2 Laser

Compared to CO2 Lasers, fiber lasers offer faster cutting speeds, lower maintenance requirements, and better energy efficiency, making them a more attractive option for many applications.

2. Fiber Laser vs. Plasma Cutting

While plasma cutting is still used for thicker materials, fiber lasers provide superior precision and versatility, especially for thinner materials and complex designs.

Cost Analysis

The Cost of Implementing Fiber Laser Cutting Technology can be significant, but the long-term benefits often outweigh the initial investment.

Initial Investment vs. Long-Term Benefits

The high upfront cost of fiber laser cutters is often offset by the savings in production time, material waste, and energy consumption over the long term.

Cost-Effectiveness in Different Scales of Operation

For small to medium-sized enterprises, fiber laser cutting can be a cost-effective solution, especially when the technology is integrated with automated systems to maximise efficiency.

Conclusion

Fiber laser cutting technology innovations have come a long way since their inception, offering manufacturers a powerful tool for precision cutting across a wide range of materials and applications. As the technology continues to evolve, we can expect to see even more exciting innovations that will further enhance its capabilities and impact on the manufacturing industry. Check out Laser Technologies today to see how we can help you integrate fiber laser cutting technology into your operations for increased efficiency and quality.

FAQs

1. What are the main advantages of fiber laser cutting technology?

A: Fiber laser cutting offers precision, speed, versatility in materials, and energy efficiency, making it a highly advantageous tool for modern manufacturing.

2. How does fiber laser cutting compare to CO2 laser cutting?

A: Fiber lasers are generally faster, require less maintenance, and are more energy-efficient than CO2 lasers, making them a more attractive option for many applications.

3. Can fiber lasers cut all types of materials?

A: While fiber lasers are versatile and can cut a wide range of materials, including metals and plastics, some materials may require specific types of lasers or cutting techniques.

4. What safety measures are in place for fiber laser cutting?

A: Modern fiber laser cutters include safety features such as automatic shutdowns and protective enclosures, and operators are trained in proper safety protocols to ensure safe operation.

5. What is the future of fiber laser cutting technology?

A: The future of fiber laser cutting technology looks promising, with ongoing innovations aimed at improving efficiency, expanding material capabilities, and integrating with other manufacturing technologies.