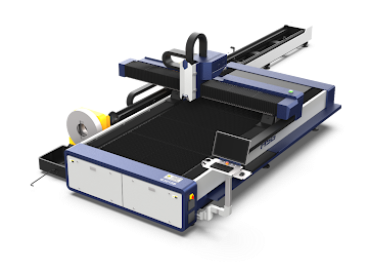

In recent years, the beginning of inception manufacturing technologies has completely revolutionized the industrial landscape of our country, India, and one such innovation is fiber laser cutting machines. All these cutting-edge tools have assembled considerable attention for their speed, versatility, and precision in a broad range of applications across numerous industries.

Whether it's electronics, aerospace, automotive, ship-building or any other small-scale enterprise, fiber laser cutting machines have proved to be necessary assets, which empower businesses with excellent efficiency and higher quality results.

The rapidly growing demand for fiber laser cutting machines in India has also led to a developing interest in understanding their cost significance. Manufacturers, entrepreneurs, and decision-makers strive to hold the critical factors that tend to influence the small laser cutting machine price in India as well as how these costs get aligned with the operational budgets & long-term profitability of these machines.

In this article, we will analyze the key drivers that directly influence the laser cutter price, including cutting bed size, power output, brand reputation, and other advanced features. By having a deep understanding of the components that contribute to the pricing format, prospective buyers will be able to make informed decisions when it comes to investing in this transformative technology, maximizing its potential, and enhancing its competitive edge.

Factors Affecting the Cost of Laser Cutting Machines

The cost of fiber laser cutting machines might vary supremely on the basis of multiple factors. We have listed down some of the primary factors that affect the pricing of all these machines. Let's have a read!

1. Laser Power

The laser power determines the cutting capability of the fiber laser cutting machine. A machine that has higher laser power, enables cutting via thicker & tougher substances, but it also increases the price of the machine.

2. Cutting Speed And Precision

Fiber laser cutting machines that provide higher cutting speed and amazing precision usually come with a higher price tag because of the advanced technology and engineering needed.

3. Cutting Area Size

The cutting area size or the working table affects the maximum size of the sheets of components that can be easily processed. Larger cutting areas normally result in higher machine prices.

4. Machine Build Quality

The build quality of the machine, materials that have been utilized, and complete construction of the machine influence its accuracy and durability. High-quality parts and construction can furthermore increase the cost.

5. Laser Source Brand

The quality and brand of the laser source do have a substantial impact on the cost of the machine. Prominent and well-known brands generally cost more, but they might also provide good performance and longevity.

6. Automation and Features

The status of automation, which includes features like advanced CNC controls, automatic nozzle changing, material handling systems, etc., can add to the overall price.

7. Support and Warranty

The level of warranty, customer support, and service provided by the manufacturer can heavily impact the laser cutting machine cost. Choosing a reliable laser cutting machine supplier from renowned manufacturers might be priced a little higher but comes with excellent support and better warranty coverage. Well-established brands that have a strong reputation in the industry usually have command over higher prices on the basis of their track record and reliability.

8. Geographic Location

The price for a small laser-cutting machine in India might vary depending on the country or region where it is being purchased because of factors like import/export taxes, local market conditions, and shipping costs.

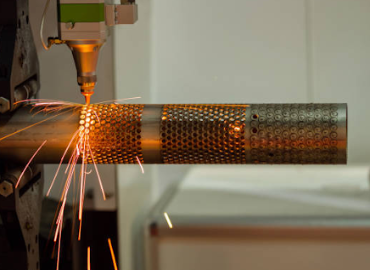

9. Supplementary Accessories

Optional accompaniments and add-ons such as rotary attachments for tube cutting or extra cutting heads can raise the overall expense.

10. Used vs. New

Purchasing a used or second-hand laser-cutting machine can enormously reduce costs when compared to buying a brand-new one. However, considerations about age, condition, and possible maintenance expenses must be taken into consideration.

11. Market Demand

Fluctuations in market demand can also have an effect on the cost of laser-cutting machines. At the time of high demand, costs might be higher, while they may be reduced to a certain level at the time of slower market conditions.

Your Next Innovation Starts Here—Explore the Best Laser Cutting Machines for 2025!

What is the Laser Cutting Machines Cost?

Basically, the entry-level fiber laser cutting machines, including 1 kW laser cutting machines price in India, that come with lower power capacity, up to 1kW, and smaller cutting areas, around 1300mm x 900mm, typically cost between INR 12 lakhs to INR 25 lakhs. This type of fiber laser cutting machine is highly suitable for small-scale businesses as well as hobbyists.

When it comes to mid-range machines, these laser cutting machines are equipped with medium power capacity, that is from 1 kW to 2 kW, and have larger cutting areas, around 1500mm x 3000mm, generally ranging from INR 25 lakhs to INR 50 lakhs. These fiber laser cutting machines are applicable for medium-sized businesses and can handle a wider range of substances and thicknesses.

Lastly, the high-end laser machines come with higher power capacity, which is above 2 kW, and have larger cutting areas, above 1500mm x 3000mm. It can amount to anywhere from INR 50 lakhs to several crore rupees. These laser cutter machines are ideal for large-scale industrial applications and they are efficient in cutting through thick materials with high precision and accuracy.

Key Takeaways

Laser cutting machines have become crucial equipment for numerous industries in India, that drive innovation and growth in the manufacturing sector. As mentioned above, the cost of these types of machines might vary on the basis of factors such as cutting area, brand reputation, features, laser power, and country of origin.

As technology resumes to advance, the best laser cutting machine price in India may come to be extra competitive, which makes them accessible to an even broader range of industries. When investing in such crucial and expensive equipment, it is necessary for industries to carefully & critically analyze their prerequisites and decide on a machine that aligns with their production requirements and long-term objectives.