Table of Contents

- Handheld Laser Welding in Sustainable Manufacturing

- Advantages of Handheld Laser Welding

- Why Choose Laser Technologies?

- Conclusion

Technologies that improve production processes while decreasing environmental effects are more important to pursue for more sustainability. Laser welding for sustainable manufacturing enhances sustainability, reduces energy consumption, and improves production.

Large-scale manufacturers, small-scale manufacturers, service providers, and businesses that want flexibility use a handheld laser welding machine. The laser welding gun is simple to regulate; the precision-focused energy produces cleaner welds with less heat distortion.

Handheld Laser Welding in Sustainable Manufacturing

As industries develop, sustainability is becoming an important factor in production processes. Handheld laser welding is an important part of the transition to green manufacturing because it provides a solution that decreases energy usage, waste, and emissions. Laser Technologies assists firms in producing cleaner, more accurate welds while supporting their environmental aims.

The laser welding machine is perfect for applications that need flexibility and mobility because of its portable design, which makes it simple for operators to transport it to various areas of a production line. Compared to conventional fixed welding setups, portable laser welding equipment provides more maneuverability when working in tight places, doing repairs, or welding intricate components.

Handheld laser welding is a crucial tool for companies seeking to enhance production processes and sustainability policies, reduce energy consumption, minimal waste, and clean operations. Laser Technologies, with its diverse range of high-quality, customisable laser welding equipment, is a dependable partner for firms aiming to enhance the efficiency, sustainability, and cost-effectiveness of their production operations.

Transform Your Welding Process - Explore Our Air-Cooled Handheld Laser Solutions!

Advantages of Handheld Laser Welding

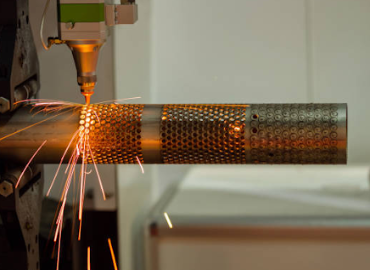

Laser welding for sustainable manufacturing offers speed and precision in various materials, resulting in higher-quality finished products due to its ability to access hard-to-reach areas.

1. Accuracy

The degree of accuracy that portable laser welding provides is one of its main benefits. Conventional welding techniques may sometimes result in problems including uneven welds, excessive material consumption, and heat distortion. On the other side, operators may produce clean, extremely precise welds with little material waste when using portable laser welding. For sensitive and complex applications, the focused laser beam is ideal because it provides precise control over the weld size.

When dealing with delicate components or thin materials, when conventional welding techniques could be excessively forceful or result in needless damage, laser welding is very advantageous. The ability to produce strong, clean welds without the need for post-processing is a huge benefit in various industries.

2. Energy Efficiency

Today's manufacturing operations are under growing pressure to decrease carbon footprints and energy use. Handheld laser welding machines are far more energy efficient than other conventional procedures in energy consumption in welding.

In contrast, laser welding generates heat using a concentrated light source, which is a considerably more efficient method. The exact targeting of energy ensures that just the required quantity is utilised to make the weld, saving waste and enhancing overall process efficiency. As a consequence, firms may lower their energy expenses while also contributing to a more sustainable manufacturing process.

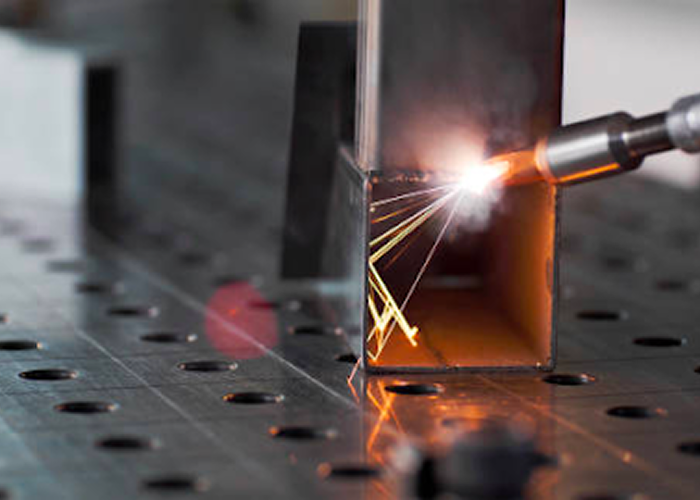

3. Reduced Heat Affected Zone

In welding, the Heat Affected Zone (HAZ) is the region of material around the weld that has been damaged by heat. A significant HAZ may cause material deformation, weakening of the material, and the creation of undesirable residual stresses. Traditional welding procedures, such as arc welding, often create a significant HAZ, which may compromise the weld's integrity and that of the surrounding material.

Handheld laser welding decreases the size of the HAZ, exposing just the weld region to extreme heat. This accuracy lowers the danger of material deformation and improves the overall integrity of the welded components. The lower heat input also results in less cooling time, which speeds up manufacturing cycles.

4. Minimal Fumes and No Toxic Gases

Traditional welding procedures, particularly those based on flames or arcs, can emit huge volumes of smoke, fumes, and poisonous gases. These pollutants may be hazardous to workers' health and provide new issues in terms of ventilation and workplace safety.

Laser welding, on the other hand, creates very little fumes and no harmful gases. Handheld laser welding is a safer choice for operators due to the absence of an open flame and the cleaner process, which reduces the need for costly ventilation systems and the health hazards connected with toxic welding byproducts. This is also consistent with increased workplace safety requirements and laws.

Handheld Laser Welding vs. MIG Welding—Discover the Best Fit for Your Needs!

5. Environmental Impact

In an age of growing environmental awareness, sustainable production is more crucial than ever. Handheld laser welding offers a highly efficient and eco-friendly alternative, contributing to sustainable manufacturing practices. Manufacturers that use portable laser welding help to minimise environmental pollution because they generate less waste, use less energy, and operate more cleanly.

Furthermore, laser welding for sustainable manufacturing allows for fewer material flaws and rework, resulting in less waste and a reduced total resource consumption. Handheld laser welding helps to promote more environmentally friendly production methods by decreasing both material and energy waste.

Extend Your Laser Welder’s Lifespan—Explore These Must-Know Tips!

Why Choose Laser Technologies?

Laser Technologies is a well-known company in the market for providing dependable, high-performance laser welding solutions. The firm has established itself as a market leader in innovative laser welding systems that are specifically developed to meet the evolving needs of contemporary production. Here are a few reasons why Laser Technologies should be your first choice for laser welding solutions:

1. Proven Expertise and Innovation

They have been at the forefront of laser technology for some years. The firm consistently invests in R&D to guarantee that its products are cutting-edge and capable of meeting the changing demands of industries throughout the globe. Whether you're dealing with metals, plastics, or composites, Laser Technologies offers innovative welding solutions that satisfy the highest accuracy and performance requirements.

2. High-quality Products

They provide the best laser welding machine to meet a wide range of industrial applications. Their solutions include advanced laser technology, allowing producers to achieve higher weld quality and operating efficiency. These systems are designed for long-term endurance, so businesses can depend on them for years of service.

3. Customisation and Flexibility

It prioritises client happiness. The organisation recognises that each production process is unique; thus, they provide customised solutions that address particular operating needs. Whether you require a portable handheld laser welding system for on-site repairs or a fully automated desktop solution for high-volume manufacturing, Laser Technologies has a solution for you.

4. Sustainable and energy-efficient solutions

It places a high priority on sustainability. The company's laser welding systems are developed with the energy economy in mind, allowing firms to lower their carbon footprint while increasing overall production. Their devices enable firms to comply with increasingly demanding environmental requirements while also contributing to a more sustainable industrial ecology.

5. Outstanding customer support

It is is devoted to delivering exceptional customer service. The organisation provides complete support throughout the purchase process, including equipment selection, installation, training, and troubleshooting. Their skilled staff guarantees that you get the most out of your laser welding equipment by optimising processes and consistently producing high-quality welds.

6. Competitive pricing

Laser Technologies provides cost-effective solutions that are excellent value for money. Their laser welding systems are reasonably priced, making them available to producers of all kinds, from tiny workshops to huge industrial facilities. The long-term savings in energy usage, material waste reduction, and increased productivity make these systems an excellent investment.

Conclusion

Laser welding for sustainable manufacturing is not only a cost-effective solution but also a way to demonstrate commitment to environmental responsibility. Businesses that use this innovative welding technology may achieve better accuracy, lower energy usage, and less environmental effects, allowing them to stay competitive in an increasingly eco-conscious world.

Laser Technologies leads the way in delivering reliable, innovative, and sustainable laser welding technologies that drive manufacturing forward. Whether your goal is to enhance production efficiency, reduce waste, or elevate product quality, Laser Technologies offers the expertise and tools to support your success in today's rapidly evolving, eco-conscious industrial environment.