When it comes to cutting acrylic materials, various technologies are available, each with its advantages and disadvantages. Laser cutting has gained significant popularity as a versatile and precise method for working with acrylic.

Let's explore the advantages and disadvantages of laser cutting in comparison to other cutting technologies for acrylic. By understanding the unique features of laser cutting and its benefits, we can choose the most suitable cutting method.

Laser cutting has experienced a steady rise in popularity as a cutting technology, and its relevance to acrylic materials cannot be overstated. Acrylic, with its versatility and wide range of applications, demands a cutting method that can deliver precision and intricate designs. Laser cutting has emerged as the ideal choice due to its ability to provide clean, precise cuts in acrylic. With the growing demand for acrylic-based products and the need for high-quality cutting results, laser cutting has become increasingly popular in various industries, including signage, architecture, arts and crafts, and manufacturing. Its versatility and ability to handle different acrylic thicknesses and shapes make laser cutting an ideal option for achieving intricate designs and exceptional precision. As we delve into the advantages and disadvantages of laser cutting compared to other technologies for acrylic, it becomes clear why laser cutting has gained such prominence and remains a sought-after method in the acrylic cutting landscape.

Credit: Alejandro Bernal

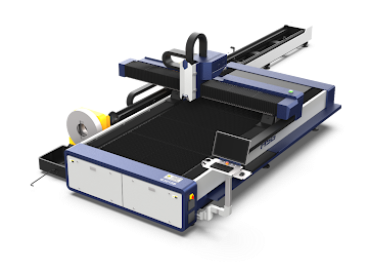

Laser Cutting: A Versatile Technology

Laser cutting offers numerous advantages for acrylic materials. Firstly, it provides exceptional precision, allowing for clean and accurate cuts. The highly focused laser beam ensures precise control over the cutting path, resulting in intricate designs and sharp corners. Secondly, laser cutting is highly versatile, capable of handling various acrylic thicknesses and shapes. It can navigate complex curves and patterns effortlessly, making it suitable for a wide range of applications.

Moreover, laser cutting is a non-contact process, eliminating the risk of material deformation or damage. The absence of physical contact also reduces the chances of contamination, ensuring a clean and uncontaminated finish. Furthermore, laser cutting minimizes material waste due to its narrow cutting width. The precise cuts and efficient nesting of shapes optimize material utilization, making it a cost-effective choice.

Credit: Getty Images

Laser cutting is a technology that utilizes a highly focused laser beam to cut through materials with precision and accuracy. The principle of operation involves the following steps:

1. Generation of Laser Beam

Laser cutting machines use a laser source, typically a CO2 (carbon dioxide) or fiber laser, to generate a concentrated beam of light. The laser beam is produced by exciting the laser medium, either a gas or a fiber, through the application of energy.

2. Beam Focusing

The laser beam passes through a series of mirrors and lenses, which focus the beam into a small, intense spot. Then focusing lenses help achieve a narrow beam width, ensuring high energy density at the cutting point.

3. Material Interaction

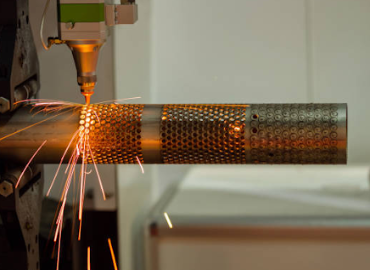

When the focused laser beam interacts with the surface of the acrylic material, it heats the material to a high temperature. The laser energy is absorbed by the acrylic, causing the material to melt, vaporize, or burn.

4. Assist Gas

To enhance the cutting process, an assist gas, such as oxygen or nitrogen, is often used. The assist gas is directed through a nozzle located near the laser beam's focal point. It helps to blow away the molten or vaporized material from the cutting path, creating a clean cut.

5. Computer Numerical Control (CNC) System

Laser cutting machines are controlled by a CNC system, which precisely guides the laser beam along the desired cutting path. The CNC system receives instructions from computer software, allowing for precise control over the cutting speed, power, and path.

6. Cutting Process

As the laser beam moves along the programmed path, it melts or vaporizes the acrylic material, creating a narrow cut. The cutting process is characterized by high precision, minimal material waste, and the ability to create intricate designs and shapes.

Overall, laser cutting relies on the intense heat generated by the laser beam to melt, vaporize, or burn through the acrylic material, resulting in precise cuts with minimal thermal distortion. The use of assist gas and CNC control further enhances the cutting process, making laser cutting an efficient and versatile technology for acrylic materials.

Advantages of Laser Cutting for Acrylic

1. Precision and Accuracy

Laser cutting stands out for its exceptional precision and accuracy, leading to clean and intricate cuts in acrylic materials. The focused laser beam allows for a narrow cutting width, enabling precise control over the cutting path. This precision ensures that the laser follows the intended design with minimal deviation. The concentrated heat generated by the laser beam melts or vaporizes the acrylic material precisely along the cutting line, resulting in smooth edges and minimal thermal distortion. Moreover, laser-cutting technology offers the ability to achieve intricate and complex designs, including sharp corners, fine details, and intricate patterns. This high level of precision and accuracy makes laser cutting a preferred choice for projects that demand immaculate and visually appealing acrylic cuts.

Laser-cutting technology excels in achieving intricate designs and fine details when working with acrylic. The highly focused laser beam allows for precise control, enabling the creation of intricate patterns, intricate shapes, and sharp corners. The narrow cutting width of the laser beam ensures clean and precise cuts, resulting in intricate details with minimal distortion. This capability opens up a world of possibilities for creating complex and visually stunning designs in acrylic materials, making laser cutting an ideal choice for projects that require intricate and precise work.

2. Versatility

Laser cutting technology is highly versatile and can effectively handle various acrylic thicknesses and shapes, making it suitable for a wide range of applications. In terms of acrylic thickness, laser cutting machines can be adjusted to accommodate different material thicknesses. The power and speed settings of the laser can be modified to optimize the cutting process for thicker or thinner acrylic sheets. This flexibility allows for precise cuts regardless of the thickness of the material, making laser cutting applicable to a broad spectrum of acrylic projects.

Furthermore, laser cutting is capable of cutting acrylic into various shapes with ease. The focused laser beam can navigate intricate curves, angles, and complex designs, allowing for the creation of custom shapes and patterns. Whether it's straight lines, curves, circles, or intricate designs, laser cutting provides the precision and versatility needed to produce accurate cuts in a wide array of acrylic shapes. This adaptability to handle different thicknesses and shapes of acrylic materials makes laser cutting an excellent choice for a diverse range of applications, including signage, architectural models, custom displays, acrylic jewelry, and more.

Laser cutting excels in effortlessly cutting complex shapes and curves in acrylic materials. The highly focused laser beam and precise control of the cutting path allow for intricate patterns, sharp corners, and smooth curves. Whether it's intricate designs or organic shapes, laser cutting provides the flexibility and accuracy needed to navigate complex geometries. This capability makes laser cutting a preferred choice for projects that require intricate and seamless cuts in acrylic, such as architectural models, artistic creations, and custom signage.

3. Non-Contact Process

One of the significant advantages of laser cutting is its non-contact nature, which eliminates the risk of material deformation or damage. Unlike other cutting technologies that involve physical contact with the material, laser cutting uses a focused beam of light to cut through acrylic without touching it. This non-contact method ensures that the material remains undisturbed and maintains its original shape and integrity during the cutting process. Additionally, avoiding physical contact also reduces the chances of contamination, as there is no transfer of particles or residues from cutting tools to the acrylic surface. This advantage makes laser cutting particularly suitable for applications that require high precision and a clean, uncontaminated finish.

4. Minimal Material Waste

Laser cutting minimizes material waste due to its narrow cutting width and precise cuts. The focused laser beam creates a thin cutting kerf, resulting in minimal material loss during the cutting process. This narrow cutting width allows for efficient nesting of shapes, maximizing the usage of the acrylic sheet. Additionally, the precision of laser cutting ensures that cuts are made accurately, minimizing the need for rework or additional material. The reduced material waste translates into cost-effectiveness, as it optimizes material utilization and reduces overall project expenses. Laser cutting's ability to minimize material waste makes it an environmentally friendly and economically viable choice for acrylic cutting applications.

Other Cutting Technologies for Acrylic

Advantages of Traditional Mechanical Cutting

1. Mechanical cutting methods offer cost-effectiveness and simplicity in cutting acrylic materials. These methods, such as sawing or routing, are often more accessible and require less initial investment compared to laser cutting.

2. They utilize conventional tools that are readily available and familiar to many fabricators. Additionally, mechanical cutting methods excel in handling thicker acrylic materials efficiently.

3. Sawing or routing machines equipped with appropriate blades or bits can easily cut through thicker acrylic sheets, making them suitable for applications that require robust and sturdy acrylic components. This combination of cost-effectiveness, simplicity, and efficient handling of thicker materials makes mechanical cutting methods a practical choice for certain acrylic cutting projects.

Disadvantages of Traditional Mechanical Cutting

1. Mechanical cutting methods have limitations when it comes to intricate designs and precision. Unlike laser cutting, which can achieve intricate details effortlessly, mechanical cutting techniques such as sawing or routing struggle to reproduce intricate designs accurately.

2. The cutting tools used in mechanical cutting may not be able to navigate sharp corners or intricate curves with the same precision as a laser beam.

3. Furthermore, the physical contact involved in mechanical cutting poses a risk of material deformation or damage.

4. The pressure exerted by the cutting tool can cause the acrylic to chip, crack, or warp, especially in delicate or thinner sections.

5. The contact between the tool and the material can also leave visible marks or rough edges, requiring additional finishing processes. These limitations make mechanical cutting methods less suitable for projects that require high precision or intricate designs in acrylic materials.

6. Laser cutting, with its non-contact approach and precise control, is better suited for achieving intricate designs and maintaining the integrity of the material.

Advantages of Waterjet Cutting

1. Waterjet cutting is known for its versatility in handling various materials, including acrylic.

2. Waterjet machines employ a high-pressure stream of water mixed with an abrasive substance to cut through materials. This method is highly effective in cutting through thick acrylic sheets with ease.

3. The powerful waterjet stream can effortlessly penetrate the acrylic, regardless of its thickness, ensuring clean and precise cuts.

4. The ability of waterjet cutting to handle thick acrylic materials makes it a preferred choice for applications that require the processing of robust acrylic components or structures.

Disadvantages of Waterjet Cutting

1. While waterjet cutting offers versatility and effectiveness, it has limitations when achieving intricate designs and fine details in acrylic materials.

2. The high-pressure water stream used in waterjet cutting can lead to material delamination or separation of layers in acrylic, especially in thicker sheets.

3. Additionally, the force of the water stream can cause edge roughness, requiring additional finishing processes.

4. Laser cutting surpasses waterjet cutting in precision and is better suited for projects requiring intricate designs and fine details in acrylic.

Credit: Alex

Essential Factors While Deciding on a Traditional or Acrylic Method

Intricacy

Factors to consider include the desired level of precision and intricacy. If the project involves intricate designs, sharp corners, or fine details, laser cutting is the optimal choice due to its exceptional precision and ability to handle complex patterns. However, if the project requires simple shapes or involves thicker acrylic sheets, traditional mechanical cutting methods may be sufficient and cost-effective.

Project Budget

The project timeline and budget are also vital considerations. Laser cutting may have higher initial costs due to equipment and setup requirements, but it offers faster cutting speeds and minimal material waste, leading to potential cost savings in the long run. Mechanical cutting methods may be more accessible and budget-friendly upfront, but they may result in higher material waste and longer production times.

Physical Characteristics

Furthermore, the physical characteristics of the acrylic material, such as thickness and fragility, should be taken into account. Laser cutting is suitable for various acrylic thicknesses, while waterjet cutting excels at cutting through thick materials. Careful consideration of the material's properties will help determine the most appropriate cutting technology.

By considering the specific requirements of the project, one can make an informed decision on the cutting technology for acrylic, ensuring the best outcome in terms of precision, efficiency, cost-effectiveness, and suitability for the project's unique needs.

Final Word

Overall, laser cutting for acrylic combines precision, versatility, a non-contact process, and minimal material waste. These advantages make it an ideal technology for achieving high-quality, intricate, and cost-effective cuts in acrylic materials. Traditional mechanical cutting methods, such as sawing or routing, have limitations when cutting acrylic. They struggle to achieve intricate designs and precise cuts, often resulting in rough edges and less accuracy compared to laser cutting. Additionally, the physical contact involved in mechanical cutting can lead to material deformation or damage, especially in delicate or thinner sections of acrylic.

On the other hand, waterjet cutting, while versatile, can cause material delamination or edge roughness due to the high-pressure water stream. It also faces challenges in achieving intricate designs and fine details due to the wider nature of the waterjet stream. These limitations make laser cutting a preferred choice for the precision and intricate cutting of acrylic materials.

When selecting a cutting technology for acrylic, it is crucial to consider the specific requirements of the project. Each cutting method, whether it be laser cutting, mechanical cutting, or waterjet cutting, has its strengths and limitations. Understanding the project's unique needs is essential for making an informed decision.