Table Of Contents

Introduction

What Is A Laser Welding Machine?

Types Of Laser Welding Machine

Few Essential Safety Precautions To Be Maintained During The Laser Welding Process

Few Safety Tips For Safe Use Of Laser Welding Machine

Latest Trends On Laser Welding

Conclusion

Key Takeaways

Introduction

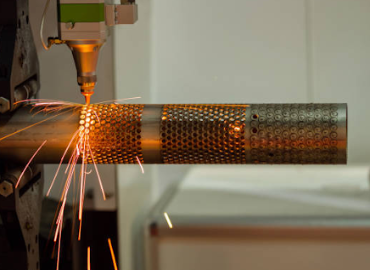

The laser welding process is a highly precise and efficient one and is utilized in varied industries, from automotive and manufacturing to aerospace engineering, for joining different types of metals and thermoplastics. Laser welding is a strong, efficient, and precise technique that utilizes a highly concentrated laser beam to adjoin different substances.

While it provides various benefits, such as minimal heat-affected zones and high precision, it also comes with unavoidable & specific safety considerations that must be addressed carefully! Ensuring the well-being of laser operators and other personnel, usage of protecting equipment, and maintaining the integrity of the definitive product are all paramount concerns when it comes to working with laser welding technology.

In this article, we will delve into the important safety precautions that must be maintained at the time of laser welding process!

What Is A Laser Welding Machine?

Laser welding is a non-contact method that enables metal parts to be convened primarily by means of a laser beam. This type of welding method is highly suitable for applications that demand high accuracy, and speed and for thin welding with minimal thermal distortion. The speed, high level of automation, and the capability of controlling the welding quality at the time of operation make the laser welding process a widely utilized technique in several industrial sectors such as electronics, medical, automotive, and beyond.

What Are The Types Of Laser Welding Machines?

Typically, the sources of laser are based on the laser medium and they are generally categorized on the basis of the material state - solid, liquid, or gas. When it comes to laser welding, solid and gas mediums are the most common ones. Let's have a look at the three main types of lasers:

a) Solid-state lasers

Solid-state lasers make use of solid materials such as slabs or glass rods as an active medium. All these materials are doped with impurities in the shape of ions in order to modify their electrical and optical characteristics. Here, the pumping source is light energy from flash tubes, laser diodes, or arc lamps. When these ions tend to interact with light, they get excited to increase energy levels.

In addition, the most general materials that are widely utilized by experts as the gain medium involve Neodymium-doped YAG, Neodymium-doped glass, and Ruby. Solid-state lasers are strong and compact with a broad spectrum of wavelengths. This type of laser produces short and high-power pulses. For this reason, solid-state lasers find their applications across various industries.

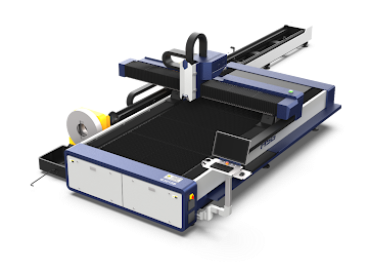

b) Fiber Lasers

Fiber laser operations are kind of similar to solid-state lasers. This medium is an optical fiber doped utilizing ions from rare components, encompassing neodymium and ytterbium. In addition, one can even utilize fillers in order to enhance the original characteristics of the workpiece.

c) Gas Lasers

This type of welding machine comes with a laser medium that is a mixture of gasses and helps in converting electrical energy into light energy. So, when the gas medium gets excited, the molecules and atoms, together, release photons. These photons collide with other enthusiastic molecules in a specific mode which leads to the amplification and the production of laser beams.

This stimulated emission of light has a greater intensity when compared to normal light. The laser beam generated is of high quality, which cannot be compared to others. There are many gas lasers out there, with the C02 laser being the most widely utilized in various sectors.

Few Essential Safety Precautions To Be Maintained During The Laser Welding Process

Here are a few important safety precautions that you must keep in mind while conducting the laser welding process:

1) Laser Control Area

You must establish a controlled laser safety area where only authorized personnel are permitted. You need to clearly mark the boundaries of this region and assign warning signs in order to indicate the existence of a laser.

2) Beam Enclosure

The laser welding area must be enclosed with laser safety barriers and enclosures in order to avoid accidental exposure to the laser beam. Ensure that the enclosure is designed appropriately so that it can contain the laser radiation.

3) Ventilation

Laser welding can produce fumes and gasses that may be hazardous. Implement proper ventilation and exhaust systems to remove these byproducts from the welding area. Use a fume extraction system to minimize exposure to fumes.

4) Eye Protection

Laser beams are too dangerous for the eyes. That's why always wear appropriate laser safety goggles or face shields that are specifically designed to obstruct the specific wavelength of the laser being utilized. Make sure that they are in good condition and correctly fitted.

Discover How Handheld Laser Welding is Shaping a Greener Future!

5) Skin Protection

Laser radiation is extremely harmful to your skin; therefore, it is strictly suggested to wear appropriate clothing, including long sleeves and pants, so that your skin remains covered properly. Make sure that the clothing set is made from materials that do not reflect the wavelength of the laser.

6) Training

Ensure that all personnel or laser operators working with laser welding equipment are adequately trained in laser safety techniques and aware of the potential hazards of laser radiation.

7) Emergency Procedures

Establish clear procedures for accidents or incidents involving lasers. This should include first-aid measures and contact information for medical professionals who are familiar with laser-related injuries.

8) Fire Safety

Laser welding tends to produce high heat, which can pose a fire risk. There must be fire extinguishing equipment present at the location, such as fire blankets or fire extinguishers, in case of any dangerous circumstances.

9) Regular Maintenance

Proper and regular maintenance of the laser welding machines is important to ensure their safety and proper functioning. Any kind of malfunction or damage must be dealt with promptly by trained personnel.

By strictly following all the above-mentioned safety precautions and making sure that all personnel are highly knowledgeable & trained properly associated with the laser welding process, you will be able to minimize the risks related to laser welding and build a safer working atmosphere. In addition, remember to always consult the guidelines provided by the manufacturer and any relevant local safety statutes for certain precautions associated with your laser welding equipment and substances.

Few Safety Tips For Safe Use Of Laser Welding Machine

During an emergency, such as an unusual laser sound or a water leak, it becomes highly important to immediately press the emergency stop button and instantly switch off the power supply.

Also, you must remember one thing before operating any laser welding machine, which is to switch on the external circulating water button. This is necessary because the laser system makes use of a water-cooling mode, and the laser power supply makes use of a cooling mode. So, if the cooling system of the laser welding machine ceases to function, it is strictly forbidden to start the system.

Another important thing you must know is that when the laser welding machine is in full operation, it is strictly prohibited to touch any circuit elements! The circuit element has a high voltage and powerful current at the time of laser welding operations, which is why only trained personnel should operate the laser welding machine.

In order to prevent any eye injury, it is recommended not to directly look at the laser when it is in full operation. In addition, it is also suggested not to utilize any external tool or equipment to reflect the laser at the time of operation.

Remember not to dismantle any components of the laser welding machine or operate it when the safety door is opened wide. Moreover, do not try to direct the laser head at any parts of the equipment.

Lastly, to prevent any explosion or fire, do not ever park any explosive or flammable substances in regions where the laser beam or laser light path can catch up!

Extend Your Laser Welder’s Lifespan—Explore These Must-Know Tips!

Latest Trends On Laser Welding Explained

The latest trends in laser welding can be marked by the betterment in technology and an increasing demand for efficiency and precision across different industries. One of the major trends is the growth of high-power fiber lasers, which provide tremendous flexibility and control in welding methods.

These types of lasers are competent enough to produce high energy densities, permitting deeper and faster welds in an expansive range of substances comprising metals and plastics. This advancement is especially beneficial for industries such as automotive and aerospace, where the requirement for lightweight and strong substances is paramount.

Another substantial development in laser welding is the integration of AI, i.e., artificial intelligence and automation, into theater welding procedures. AI algorithms are being utilized in order to optimize welding parameters in real-time, making sure that consistent quality is maintained and eliminating defects. Besides, robotic systems are coming to be more sophisticated, encouraging precise and complex welding chores. As technology continues to develop, laser welding is anticipated to play an even more pivotal part in modern manufacturing techniques!

In Conclusion

To conclude, safety precautions are paramount in any operations related to laser welding processes! The laser welding technique is an efficient and powerful one, and it poses specific threats that should be handled carefully in order to protect the laser operator and the surrounding atmosphere. By adhering to a detailed set of safety guidelines, laser operators will be able to minimize the potential risks that are related to laser welding.

Curating an organized and controlled work environment, labeled with warning signs and specified laser hazard zones, helps in maintaining a safe working setting. Maintaining & inspecting the laser equipment regularly makes sure that the laser welding machines function in a smooth manner and pose zero to minimal danger of any kind of malfunction.

By precisely sticking to all these safety precautions and fostering an environment of safety consciousness, the laser welding process can continue to remain a valuable and secure technique for joining different substances in numerous industries, ensuring the well-being of operators and the integrity of the laser welding procedure. In the goal of precision and efficiency, the safety of those involved should always remain a top priority!

Key Takeaways

Laser operators must wear appropriate personal protective equipment (PPE), including safety glasses, face shields, gloves, etc.

Ensure appropriate ventilation and utilization of fume extraction systems in order to eliminate harmful fumes and gasses.

Always try to keep the work area neat & clean and free of clutter to stave off tripping hazards.

Ascertain that the laser welding machine is properly calibrated and well-maintained.

Provide training and certification to laser operators in laser safety methods and equipment function.

Prevent any straightforward exposure to the laser beam and utilize laser safety obstacles or curtains.

Remember to monitor and regulate the laser power and certain parameters to dissuade overheating and material harm.

Be equipped with valuable knowledge regarding the potential fire hazards and have fire extinguishing equipment easily accessible.

Retain emergency shutdown techniques and first aid supplies readily available.

Uphold precise communication and determine an emergency response plan with your laser operators or coworkers.

Strictly adhere to the guidelines provided by the manufacturer as well as industry standards for laser welding safety.