Table of Content

Introduction

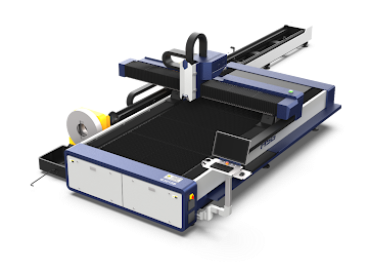

Laser Welding Machines (LWM) are the epitome of precision and innovation in welding technology. Their importance cannot be overstated in modern industries where intricate, high-quality welding is essential. However, a comprehensive and proactive maintenance regimen is indispensable to ensure these highly specialized machines' seamless and extended operation. In this article, we embark on a journey deep into LWM maintenance, providing extensive insights, detailed tips, and a wealth of information to ensure your equipment's longevity and peak performance.

How does a Laser Welding Machine work?

Before delving into maintenance procedures, it's essential to grasp the fundamental workings of LWMs. Laser Welding Machines operate on the principle of utilizing a highly focused laser beam to apply intense heat to the welding area. This laser beam, precisely controlled, induces localized melting of materials, resulting in a strong and precise weld upon cooling. The key advantage of LWMs lies in their unparalleled precision and ability to tackle intricate welding tasks with unmatched accuracy. Let's explore this process in more detail.

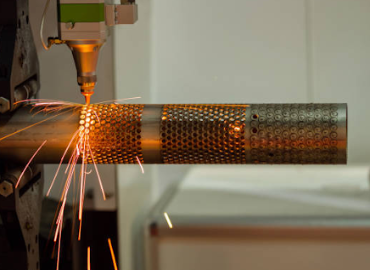

The laser beam generated by the LWM is typically emitted from a laser source, often a neodymium-doped yttrium aluminum garnet (Nd: YAG) or fiber laser. This beam is then directed through a series of optical components, including mirrors and lenses, to focus it to an incredibly fine point at the welding location. The concentration of energy at this focal point generates intense heat, causing the material to melt and fuse together rapidly.

The precision of this process is further enhanced by the ability to control various parameters, such as laser power, beam diameter, pulse duration, and repetition rate. These controls allow operators to tailor the welding process to the specific requirements of each job, ensuring consistent and high-quality results.

Industry Applications of Laser Welding Machines

The versatility and precision of laser welding machines have led to their widespread adoption across a diverse range of industries, highlighting various applications of laser technology.- Automotive:

Laser Welding Machines are integral to the automotive sector, contributing to the production of critical components such as exhaust systems, chassis parts, and transmission components. Their use ensures structural integrity, longevity, and the highest levels of safety.

- Aerospace:

In the aerospace industry, where precision and reliability are paramount, Laser Welding Machines are used extensively to weld components like turbine blades, fuel nozzles, and engine parts. These applications demand the utmost precision and quality.

- Electronics:

Laser Welding Machines are employed to weld microelectronics sensor components and to solder delicate circuitry. The integrity of electrical connections is preserved, resulting in reliable electronic devices.

- Medical Devices:

The production of medical devices like stents, catheters, and surgical instruments benefits from the precision of Laser Welding Machines. These machines ensure the highest standards of safety and performance in medical equipment.

- Jewelry:

In the jewelry industry, Laser Welding machines shine when it comes to the precise welding of intricate and valuable pieces. Their ability to create clean, localized welds preserves jewelry's aesthetic and structural integrity.

Tips to Maintain the Laser Welding Machine in 2025

Comprehensive maintenance practices are imperative to guarantee the consistent and efficient operation of your Laser Welding Machines. Here are detailed tips for each maintenance aspect:

1. Regular Cleaning:

Regular cleaning is the foundation of Laser Welding machine maintenance. Establish a strict cleaning routine to protect the optical components and laser delivery system from performance-diminishing contaminants. Utilise specialized lint-free wipes and manufacturer-approved cleaning solutions. Pay careful attention to optical surfaces to ensure they remain pristine and free from dust, debris, or contaminants that could lead to scratches or permanent damage.

2. Cooling System Maintenance:

The cooling system is the lifeblood of your Laser welding Machines. Regularly inspect and clean all components, including filters and coolant reservoirs. Monitor the coolant level, ensuring it remains within the manufacturer's recommended parameters. Adhere to prescribed coolant replacement intervals to prevent overheating and maintain the machine's optimal operating temperature.

3. Optics Inspection:

The quality of the laser beam is intrinsically tied to the condition of the optics. Regularly assess the state of the laser optics, including mirrors and lenses. Promptly replace any damaged or worn-out optics to maintain the optimal laser beam quality, ensuring consistently high-quality welds.

4. Calibration and Alignment:

Precision is the hallmark of Laser Welding Machines, and calibration and alignment are pivotal to maintaining this precision. Follow the manufacturer's guidelines for regular laser beam calibration and alignment. Misaligned beams can result in subpar welds and potential damage to the Laser Welding Machines, making adherence to these guidelines imperative.

5. Check Gas Supply:

The shielding gas supply is a critical aspect of the welding process. Vigilantly monitor and maintain the gas supply system, ensuring the uninterrupted flow of shielding gases such as argon or helium. Detect and address any gas leaks or insufficient gas flow immediately, as these issues can compromise weld quality and potentially damage the Laser Welding Machines.

6. Software Updates:

Stay abreast of control software updates provided by the manufacturer. These updates often encompass enhancements in performance, safety features, and operational efficiency. Regularly updating your software ensures that your Laser welding machines operate at their full potential, taking advantage of the latest technological advancements.

7. Operator Training:

Invest significantly in operator training to ensure proficient use and maintenance of the Laser Welding Machines. Well-trained operators are less likely to misuse or mishandle the equipment, reducing the risk of damage and improving overall operational efficiency. Operator training should encompass both the technical aspects of the machine and safety protocols.

How to Choose the Right Laser Welding Machines in 2025

Selecting the appropriate Laser Welding Machine is a critical decision that directly impacts your efficiency and productivity. To make an informed choice, consider these expanded factors during your selection process:

a. Welding Requirements

Conduct a comprehensive assessment of your specific welding needs. Consider factors such as material types, thicknesses, and desired weld quality. Different LWM models may excel in distinct applications, so choose one that aligns perfectly with your requirements. Understanding your welding needs is the first step toward selecting the right machine.

b. Power and Beam Delivery

The power level and beam delivery system of the Laser Welding Machine should be precise and match your application needs. Ensure that the machine can deliver the desired results without compromising on quality. Consider the range of materials you'll be working with and the depth of penetration required. The right combination of power and beam delivery is essential for efficiently achieving the desired welding results.

c. Maintenance Requirements

Investigate the manufacturer's track record for machine reliability and the availability of comprehensive service and support options. Robust and accessible maintenance support can minimize downtime and ensure the longevity of your investment. Evaluate the ease of access to critical components for maintenance and the availability of spare parts. A machine with good maintenance support can save you time and money in the long run.

d. Budget

Establish a clear budget for your Laser Welding Machine acquisition. Explore machines that offer the best balance of features, performance, and cost-effectiveness within your financial constraints. Remember that long-term maintenance costs should also factor into your budget considerations. It's essential to strike a balance between your budget and the machine's capabilities to ensure a cost-effective investment that meets your welding needs.

Conclusion

Maintaining Laser Welding Machines is a multifaceted and meticulous undertaking, critical for achieving consistent, high-quality welds and extending the operational life of these sophisticated industrial tools. By diligently following the comprehensive maintenance tips and considerations outlined in this guide, you can maximize the efficiency and longevity of your Laser Welding Machine, contributing to the overall success of your welding operations.

Moreover, when selecting the right Laser Welding Machine, a thorough understanding of your needs, budget considerations, and maintenance support will help you make an informed investment poised to deliver long-lasting value to your organization. Whether in the automotive, aerospace, electronics, medical, or jewelry industry, properly maintaining your LWM ensures you can continue to meet the highest standards of quality and precision, ultimately driving success and innovation in your field.

In conclusion, Laser Welding Machines are not merely tools but instruments of precision and reliability. With careful maintenance and thoughtful selection, they can be your partners in achieving excellence in welding and manufacturing, powering today's and tomorrow's industries.