Table of Content

- 5 Best Laser Cutting Machines in 2025

- Why Choose Laser Technologies?

- After-Sales Support from Laser Technologies

- Conclusion

Laser-cutting machines revolutionize industries, providing precision, efficiency, and versatility in manufacturing processes. Whether you're working with sheet metal, tubes, or complex shapes, investing in the right laser-cutting machine is crucial for maximizing productivity in your operations.

Laser Technologies offers Laser Cutting Machines for Sale to optimize your workflow. Our team of professionals will help you identify the ideal solution for your company. Book your demo now. Let's explore some of the best laser-cutting machines to look at in 2025.

Top 5 Best Laser Cutting Machines To Look in 2025

Let's now discuss various types of laser-cutting machines.

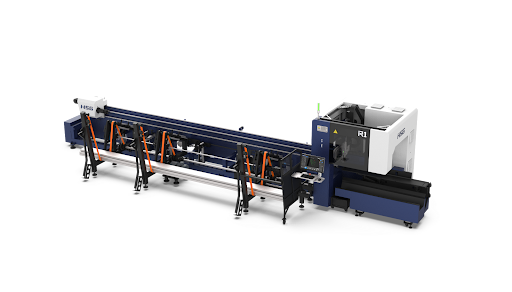

1. R1 - High-Speed Tiny Tube Laser Cutting Machine

R1 Tiny Tube Laser Cutting Machine is an excellent choice for production involving cutting of small-diameter tubes with precision and speed. This is the best fiber laser cutting machine for sale, designed for industries requiring intricate and accurate tube cuts.

Key Features:

- Compact Design: The R1 is known for its compact form factor, making it ideal for companies with limited space but still needing high-performance cutting capabilities.

- Efficient Multi-Mode Material Loading: The R1 Series laser cutting machines feature an automatic material rack capable of loading materials in just 20 seconds, accommodating tubes ranging from 20mm to 120mm and lengths of 4m to 6.5m.

- Chuck Jumping Technology for Minimal Tailings: The R1 Series machines utilize a chuck jumping mechanism for efficient cutting, reducing tailing lengths and ensuring accuracy in long tube cuts, with optional servo chuck leaping systems for increased efficiency.

- Automated Loading System: With an automatic tube feeding and unloading system, the R1 significantly reduces manual labor and boosts productivity.

- Intelligent Bus Operating System for Enhanced Productivity: The R1 Series is a versatile processing system with an intelligent bus operating system, nesting software, and professional price calculations for efficient production workflow management.

The R1 is perfect for automotive, medical, and aerospace businesses due to its compact size and high-speed cutting.

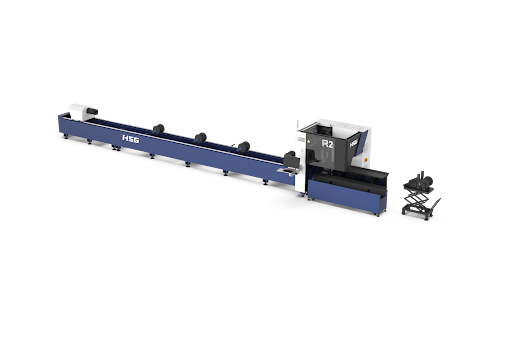

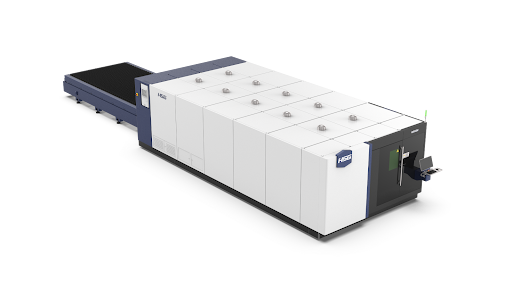

2. R2 - Double-chuck Universal Tube Laser Cutting Machine

R2 Tube Laser Cutting Machine is designed for high-volume production with its double-chuck system, allowing for continuous cutting without the need for manual intervention. This is one of the best buy laser-cutting machines in India.

Key Features:

- Dual Functionality: R2 can cut both flat sheets and round tubes, making it an ideal choice for your cutting processes.

- Large Processing Area: The R2 is designed to handle larger workpieces, accommodating different tube sizes and flat sheet material for high-volume production.

- Easy-to-Use Interface: The intuitive control system and user-friendly software allow operators to quickly set up the machine, reducing setup times and operational learning curves.

The R2 series, with rectangular-circle chucks, offers efficient tube cutting for various tube types up to 300 kg, making it a valuable asset in high-volume production environments.

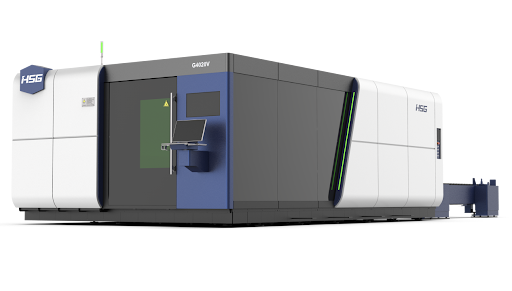

3. GV Series - Flagship Fiber Laser Cutting Machine

GV Series Fiber Laser Cutting Machine represents laser cutting technology, offering superior performance, precision, and automation. It’s ideal for heavy-duty operations where the highest quality and efficiency are required.

Key Features:

- Advanced thick sheet fiber cutting: The GV series offers a selection of laser cutting heads ranging from 6 to 60 kW. Enhanced laser power allows for the rapid cutting of thick sheet metal, optimizing speed, and efficiency in demanding applications.

- Full direct drive German-made linear motor: The GV series features a professional triaxial linear motor system for exceptional speed, acceleration, and repeatability, with German-engineered Rexroth integrated measuring systems for IP67-rated protection.

- Optimal component maintenance: Smart nozzle cleaning, automatic nozzle replacement, and nozzle life detection are essential for reliable operations, enhancing part quality, and streamlining the cutting process.

- Double-sided four-guide rail system: The system uses German-engineered rexroth guide rails, a dual-guide configuration, for stability and reliability, with roller guide rails providing superior load-bearing capacity and rigidity.

The GV Series is a top-tier choice for large-scale manufacturers and industries that demand high-quality, fast, and precise cutting of thick metal sheets.

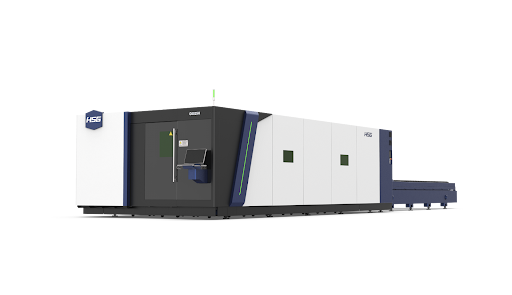

4. GH Series - Fiber Laser Cutting Machine

GH Series Fiber Laser Cutting Machine is designed for precision and high-speed cutting, with a focus on delivering reliable performance and minimal downtime.

Key Features:

- Super Dynamic Performance: The machine can achieve a maximum linkage speed of 200 m/min and a maximum linkage acceleration of 4.0 G, facilitating efficient sheet processing scenes.

- Upgraded Matrix Machine Bed: The new matrix machine and welding design significantly enhance the rigidity of the entire machine bed structure, reducing the negative impact on the machine bed.

- Bus Control System: The upgraded bus control system offers a green, intelligent, and user-friendly system with advanced features such as intelligent path optimisation, smart vibration control, torque protection, and air pressure correction.

The GH Series is perfect for companies that need a durable and energy-efficient laser-cutting machine capable of handling a variety of materials.

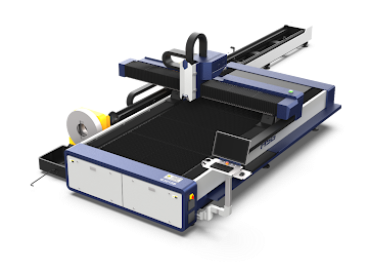

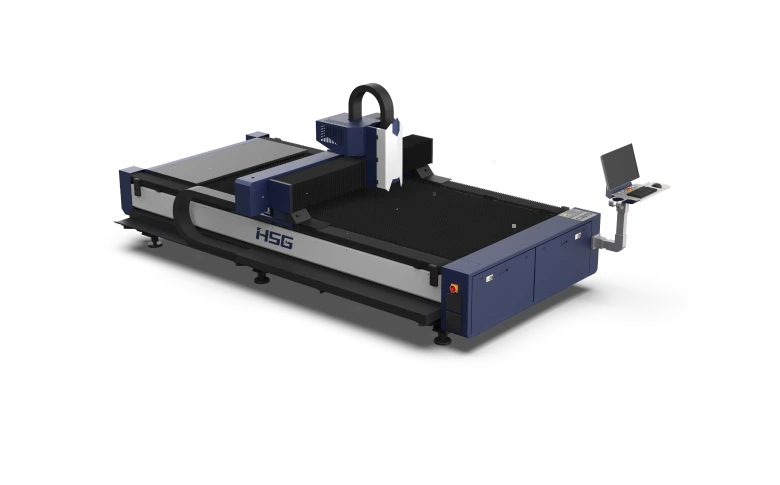

5. C Series - Single Platform Laser Cutting Machine

C Series Single Platform Laser Machine is a compact, single-platform machine designed for cutting metal sheets with precision and speed. It's the best laser cutter for small business to medium-sized production runs.

Key Features:

- Small Size Bulk Transport: The C3015 is an open-type structure with a single platform, allowing loading from various sides, and can be shipped in a 40HQ standard container for cost savings.s.

- Affordable and Efficient: The C Series provides a cost-effective cutting solution without compromising on quality or efficiency, making it ideal for small businesses and startups.

- Bus Control System: The system, compatible with international brand codes, enables data transmission via the EtherCAT bus, and monitors core components in real-time.

- Massive Production Database: The machine handler utilises advanced cutting technologies from the database to cut sheets of various metals and thicknesses, including air cutting, counterboring, PFC, and lightning-fast piercing.

- Professional Nesting Software: The machine optimises the cutting path, reducing operational time, and utilizes a smart typesetting algorithm to increase material utilization.

The C Series is an excellent option for businesses that require high-quality cuts on metal sheets without the need for a large-scale investment.

Why Choose Laser Technologies?

It is renowned for its innovative approach to purchasing the best fiber laser cutter for your business. Here’s why you should choose Laser Technologies:

1. Advanced Technology:

It integrates state-of-the-art innovations in each machine, ensuring high-quality cuts, fast processing, and minimal maintenance.

2. Customisable Solutions:

From tubes to flat sheets, Laser Technologies has the best laser cutting machines in India, catering to a variety of materials and applications, making them suitable for various industries.

3. User-Friendly Interface:

With intuitive interfaces and control systems, operating their machines is simple and efficient, even for those with minimal technical expertise.

Their machines are built to ensure a long-lasting and reliable solution, making your go-to choice of laser cutting machine suppliers near me.

After-Sales Support from Laser Technologies

One of the most compelling reasons to choose Laser Technologies is their excellent After-sales Support. They are committed to ensuring the longevity and optimal performance of their machines. Here's how they support you:

1. Installation & Training:

It offers comprehensive installation services and hands-on training for operators, ensuring smooth operations right from day one.

2. Maintenance & Repair Services:

With a dedicated team of professionals, it provides regular maintenance services and prompt repairs to minimize downtime and extend the lifespan of your machine.

3. Spare Parts & Upgrades:

The company ensures the availability of high-quality spare parts and offers machine upgrades to keep your equipment at the cutting edge of technology.

Conclusion

Laser Technologies is a leader in laser cutting technology with a competitive industrial laser cutting machine price and custom laser cutting machines. With an extensive range of laser cutting that caters to diverse industries and needs, businesses can rely on Laser Technologies for top-tier solutions.

Whether you need a small-diameter tube cutting machine, a versatile option like the R2, or a high-performance flagship system like the GV Series, Laser Technologies has you covered. With excellent after-sales support these machines offer a pathway to improve productivity in your operations. Check out the best laser cutting machines in 2025 now.