Table of Content

- Understanding Ultra High Power Laser Cutting Machines

- Key Features of Laser Technologies UHP Laser Cutting Machines

- Applications Across Industries

- Benefits of Choosing Laser Technologies UHP Laser Cutting Machines

- Why Choose Laser Technologies?

- Conclusion

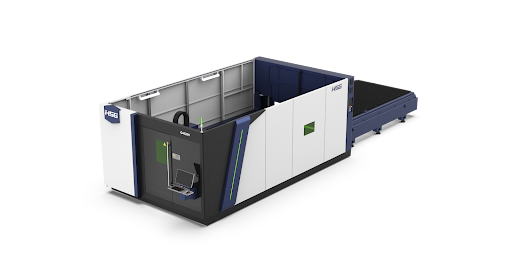

The demand for accuracy, efficiency, and adaptability has never been stronger in the fast-changing field of sheet metal fabrication. Ultra High Power laser cutting technology has emerged as a pivotal solution, enabling manufacturers to meet these stringent requirements with accuracy and speed. Laser Technologies, a leader in innovative laser solutions, offers an advanced Ultra High Power(UHP) laser cutting machine designed to revolutionise metal fabrication processes.

Ultra High Power Laser Cutting Technology is constantly evolving to meet the demands of the industry, and Laser Technologies is at the forefront of these advancements. With their advanced UHP laser cutting machine, manufacturers can stay ahead of the competition and achieve unparalleled precision in their fabrication processes.

Understanding Ultra High Power Laser Cutting Machines

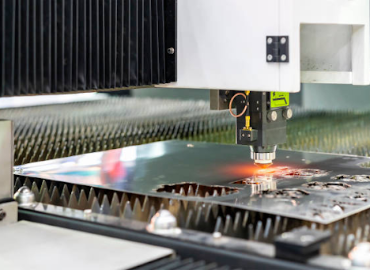

Ultra High Power laser cutting involves lasers with power outputs typically 3,000W to 6,000W. These high-powered lasers can cut through with remarkable precision. The concentrated energy of the laser beam melts, burns, or vaporises the material, resulting in clean and precise cuts with minimal thermal distortion.

Key Features of Laser Technologies UHP Laser Cutting Machines

Laser Technologies UHP Laser Cutting Products are engineered to deliver exceptional performance and incorporate several advanced features. These machines offer high-precision cutting capabilities, with the ability to cut a wide range of materials with speed and accuracy.

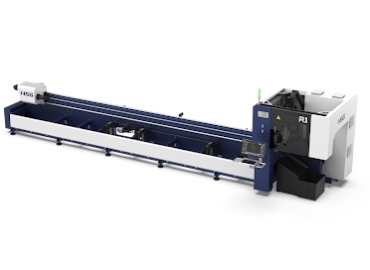

1. Double Exchange Platforms for Enhanced Productivity

The double exchange platform system, which uses 16A-wide chains and taper pins to position them precisely, is a standout feature. This design allows for simultaneous loading and unloading of materials, significantly reducing downtime and boosting productivity. The entire exchange process is monitored via a PLC touchscreen, providing operators with real-time control and insights.

2. Advanced Alpha T Bus CNC System

At the core of these machines lies the Alpha T Bus CNC system, facilitating high-speed and stable data transmission through a network cable. This system offers functionalities such as micro-connection cutting to minimise material distortion, active obstacle avoidance for safe operations, proactive maintenance alerts, and real-time monitoring of core components. Additionally, the integrated software optimises material utilisation, reducing waste and enhancing cutting efficiency.

3. Precision Engineering with German Components

How Precise Is Laser Cutting? To ensure synchronised movement and superior accuracy, the machines are equipped with German-engineered WITTENSTEIN Alpha speed reducers, gear wheels, and racks. These high-quality components contribute to the machines' durability and consistent performance, enabling flawless cuts across various materials and thicknesses.

4. Customisable Laser Power Options

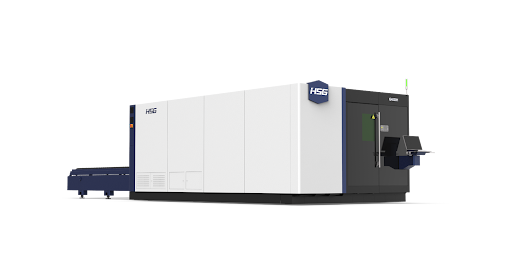

How powerful are metal-cutting lasers? Metal cutting lasers are incredibly powerful, able to cut through various thicknesses of metal with extreme precision. For instance, the GX Series laser cutting machines offer a wide range of power options from 3000W to 30000W.

The reflectance and thermal conductivity of the material affect the efficiency of the cutting process, making it crucial to choose the right laser power for each specific material. It also depends on how different materials interact with laser-cutting machines.

Laser Technologies UHP laser cutting machines are designed to handle a broad spectrum of materials with varying thicknesses. The high-speed operation ensures quicker project turnaround, while the precision cutting minimises material wastage. Whether dealing with intricate patterns or large components, these machines deliver consistent and high-quality results.

Applications Across Industries

The ultra-high-power laser cutting makes it indispensable across various manufacturing and electronics sectors. Its precision and speed make it a valuable tool for cutting a wide range of materials with high accuracy.

1. Automotive Manufacturing

The automotive industry is heavily reliant on precision manufacturing to ensure vehicle safety, performance, and aesthetic appeal. UHP laser cutting plays a pivotal role in producing critical automotive components such as body panels, chassis parts, and complex structural elements, ensuring their precision and quality. It enables the creation of intricate designs with tight tolerances and smooth edges, essential for ensuring both the structural integrity and visual appeal of automotive parts.

2. Aerospace and Defence

In the aerospace and defence industries, UHP laser cutting is integral to manufacturing high-performance, high-reliability components where even the smallest error can have consequences. UHP lasers can precisely cut a wide range of parts, from turbine blades and exhaust systems to airframe components and satellite parts. They can do this because they can work with the tight tolerances needed in these fields, which protects the quality of the parts.

3. Electronics and Semiconductor Manufacturing

The electronics and semiconductor industries demand precision and efficiency, especially as devices continue to shrink in size while becoming more powerful. UHP laser cutting facilitates the production of miniature components, including microchips, PCBs (printed circuit boards), and heatsinks, with extreme accuracy. The technology allows manufacturers to cut delicate, intricate patterns and geometries required for modern electronics without causing thermal damage or burr formation.

4. Medical Device Manufacturing

The medical device industry requires extreme precision in the manufacturing of critical components such as surgical instruments, implants, and diagnostic equipment. UHP laser cutting ensures the accuracy needed for these components. Moreover, the technology’s non-contact nature minimises the risk of contamination, which is paramount in medical applications. UHP laser cutting also allows for the efficient, high-volume production of devices with minimal downtime, ensuring the timely availability of life-saving equipment.

Benefits of Choosing Laser Technologies UHP Laser Cutting Machines

Investing in Laser Technologies UHP laser cutting machines offers numerous advantages. These machines provide high-precision cutting, allowing for intricate designs and minimal material waste.

1. Enhanced Productivity

The double exchange platform design minimizes idle time, allowing for continuous operation and faster project completion, which is essential for high-volume production environments.

2. Superior Precision and Consistency

How Precise Is Laser Cutting? The advanced CNC system and high-quality components ensure that each cut is executed with exacting precision, maintaining consistency across all projects and reducing the need for secondary processing.

3. Cost Efficiency

Optimized material usage through nesting software reduces waste, and proactive maintenance alerts help prevent unexpected downtime, leading to lower operational costs and improved profitability.

4. User-Friendly Operation

The intuitive PLC touchscreen interface simplifies machine operation, reducing the learning curve for new operators and enhancing overall operational efficiency.

5. Durability and Reliability

Built with premium components and engineered for longevity, these machines provide reliable performance over time, ensuring a solid return on investment.

Also Read, The Pros and Cons of Laser Cutting Compared to Other Cutting Technologies

Why Choose Laser Technologies?

Laser Technologies is committed to delivering modern laser solutions that meet the evolving needs of modern manufacturers. With a focus on quality, innovation, and customer satisfaction, the company stands out as a trusted partner in the industry. Their dedication to continuous improvement and customer support sets them apart from competitors, making them the top choice for businesses seeking reliable laser technology solutions.

Conclusion

The GX Series Laser Cutting Machine by Laser Technologies empowers manufacturers with ease of work and efficiency. Experience the future with Laser Technologies by reducing downtime in laser cutting. Do contact us for the Double Exchange Laser Cutting GX Series Machine demo.